- Product Details

Universal Joint Drive Balancing Machine

Overview

The balancing machine is an instrument used to determine the unbalance of the rotor. The balancing machine is a hard-supported balancing machine. The swing frame is very rigid. The measurement result of the dynamic balancing machine is used to correct the unbalance of the rotor, so that the vibration generated when the rotor rotates or acts on the vibration on the bearing is reduced to the allowable range to achieve the purpose of reducing vibration, improving performance and improving product quality.

uses universal joints to connect the main shaft of the balancing machine with the rotor. The characteristic of coupling drag is that it is suitable for rotors with irregular appearance, can transmit larger torque, and is suitable for dragging rotors with large wind resistance such as fans. The disadvantage of coupling drag is that the unbalance of the coupling itself will affect The rotor has an impact (so the coupling must be balanced before use), and interference will also be introduced to affect the accuracy of the balance. In addition, a large number of connecting disks must be made to adapt to different types of rotors.

Application

It is mainly a hard-bearing balancing machine that combines high-precision mechanical parts and advanced electrical parts into one. This series of products is one of the universal universal joint drive balancing machines developed, designed and manufactured by our company based on the core technology at home and abroad. It is currently an internationally advanced model, which is applied to various rotating workpieces, such as centrifuge rotors, fan rotors, centrifugal impellers, large water pump rotors, generator rotors, internal combustion engines, dryers, screen baskets, crushers, crushers, Train wheel sets, steam turbines, agricultural machinery and other industries.

This machine adopts universal joint transmission device, and the universal joint shaft can move in a small range without clearance to facilitate the connection between the workpiece and the universal joint. Its characteristics have the advantages of high precision, high efficiency, convenient operation, intuitive display, rapid measurement, stable performance, and the use of frequency conversion speed control device to control the speed.

The electromechanical measurement system can be equipped with a microcomputer digital display measurement system or a computer measurement system.

Purpose

An unbalanced rotor generates a pressure on its supporting structure and the rotor itself during its rotation, and causes vibration. Therefore, the dynamic balance of the rotor is very necessary. The balancing machine is to check the dynamic balance of the rotor in the rotating state. The function of dynamic balance is:

● Improve the quality of the rotor and its components

● Reduce noise

● Reduce vibration

● Improve the trial life of supporting parts (bearings)

● Reduce user discomfort

● Reduce the power consumption of the product

Technical Parameters

Model | HZ-9701C-8000 |

Max Mass of Workpiece(kg) | 8000 |

Max Diameter of Workpiece | Ø2100mm |

Bath length | 6000mm(Effective length 5000) customize |

Roller bearing journal range(mm) | Ø40~ Ø320 |

Balance speed (r/min) | 100-1000 (Frequency conversion stepless speed regulation) |

Universal-joint transmission torque(N.m) | 1250 |

Motor Power (KW) | 22 (Invertermotor) |

The smallest achievable residual unbalance (g.mm/min) | emar≤1 |

Unbalance reduction rate (%) | URR≥90% |

Measuring system | Microcomputer digital electrical measurement system(optional computer measurement system) |

Note: The technical parameters of the above series of balancing machines are for reference only. The specific parameters and quotations need to be determined according to the actual situation of the rotor of the user's workpiece, and can also be customized. | |

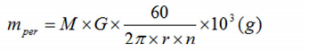

Unbalance amount calculation

Where mper is the allowable unbalance:

M: represents the weight of the rotor, the unit is kg

G: represents the balance accuracy grade of the rotor, the unit is mm/s

r : represents the correction radius of the rotor, the unit is mm

n: represents the speed of the rotor, the unit is rpm.