- Product Details

Model HZ-9701F Crankshaft Balancing Machine

Overview

HZ-9701F is adopts ring-belt transmission to ensure the balance quality and accuracy of the workpiece. The ring-belt transmission is convenient to load and unload, and the work efficiency is high. It is widely used in the balance

Production Description

• Specially designed brackets transmit mechanical force with low vibration damping and high rigidity

• Durable and reliable sensor possesses good linearity

• Permanent calibration brings high accuracy with a permission of large initial unbalance amount

• Belt-driving offers higher precision and easier operation

• Advanced electrical measuring system and friendly man-machine interface

• Modular design offers a wide range of application

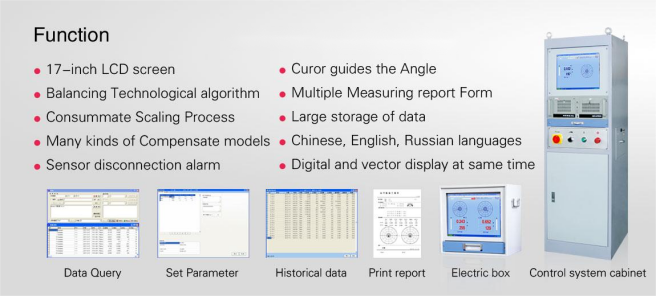

Function

l Specially designed brackets, transmit force effectively

l High sensitivity sensor, good linearity

l Permanent calibration measurement principle

l Belt-driving offers higher precision and easier operation.

l Equiped with advanced measuring system.

l Modular design offers a wide range of application

Range of Application

This balancing machine is widely used in balancing rotatable bodies, such as kinds of medium-sized and small-sized motors rotors, impeller, fans, crankshaft, turbocharger, water pump, roller, grinding wheel, main shaft of machine tool , textile machinery, tool , spindle, etc .. Driven by belt, equipped with Variable speed motor to drive .Which ensures high quality balancing and precision. quick booting ,easy operation. and high efficiency

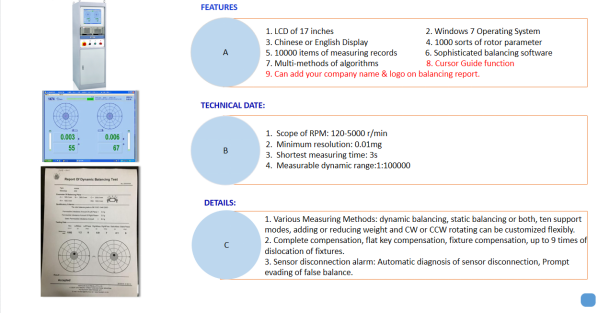

Electrical Measuring System (Option)

Control System

The first step is that we want to do the motor rotor balance on the precise measurement station, operation, according to the sensor capture, through the main board, filter board, A / D acquisition card, passive floor, for the conversion, selection of the motor rotor vibration signal, calculation, so as to measure the phase and size.

Then the data is displayed on the display screen, the dynamic balance machine detection system is mainly through the program input original data, in the internal calculation process, according to the transmission of data between each electronic component, and then appear with the graphical interface, so that we can normally identify the effect. The data information in the dynamic balance machine is coordinated and controlled through the data bus and the control bus

Production Parameters

Technical data at a glance | HZ-9701F |

Max Mass of Workpiece (kg) | 50 |

Max Diameter of Workpiece (mm) | 700 |

Distance between Two Support Bearings (mm) | 80--700 |

Journal Diameter Scope of Workpiece (mm) | 8~80 |

Diameter Scope of Driving Belt (mm) | 18~200 |

Rotation Speed when the Diameter of Driving Belt is 100mm (r/min) | 700/1050 Stepless speed regulation |

Motor Power (kw) | 0.75 Frequency conversion |

Min Achievable Residual Unbalance Amount (emar) | 0.5g· mm/kg |

Measuring system