- Product Details

Main functions:

Xenon Lamp Testing Chamber make the samples exposed to the high temperature and alternating back to the circle of light and moisture environment to test the materials. This machine use xenon lamp tube to simulate the sunlight radiation, and use condensation water and spray water to simulate the dew and rain. This instrument Xenon Testing Chamber only use a few days or weeks time, to realize the condition or the parts aging damage state in outside environment in few months or years. Including fade, color change, fracture, crack, wrinkle, foaming, embrittlement, strength reduction, oxidization and so on.Xenon Lamp Test Chamber Corresponding standard:

ASTM G155-05a Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials1

Xenon Test Chamber Applicable industries:

Applied to control the product quality, such as electronic, plastic products, electrical appliances, instruments, food, vehicles, metals, chemicals, building materials, aerospace, medical care and so on.

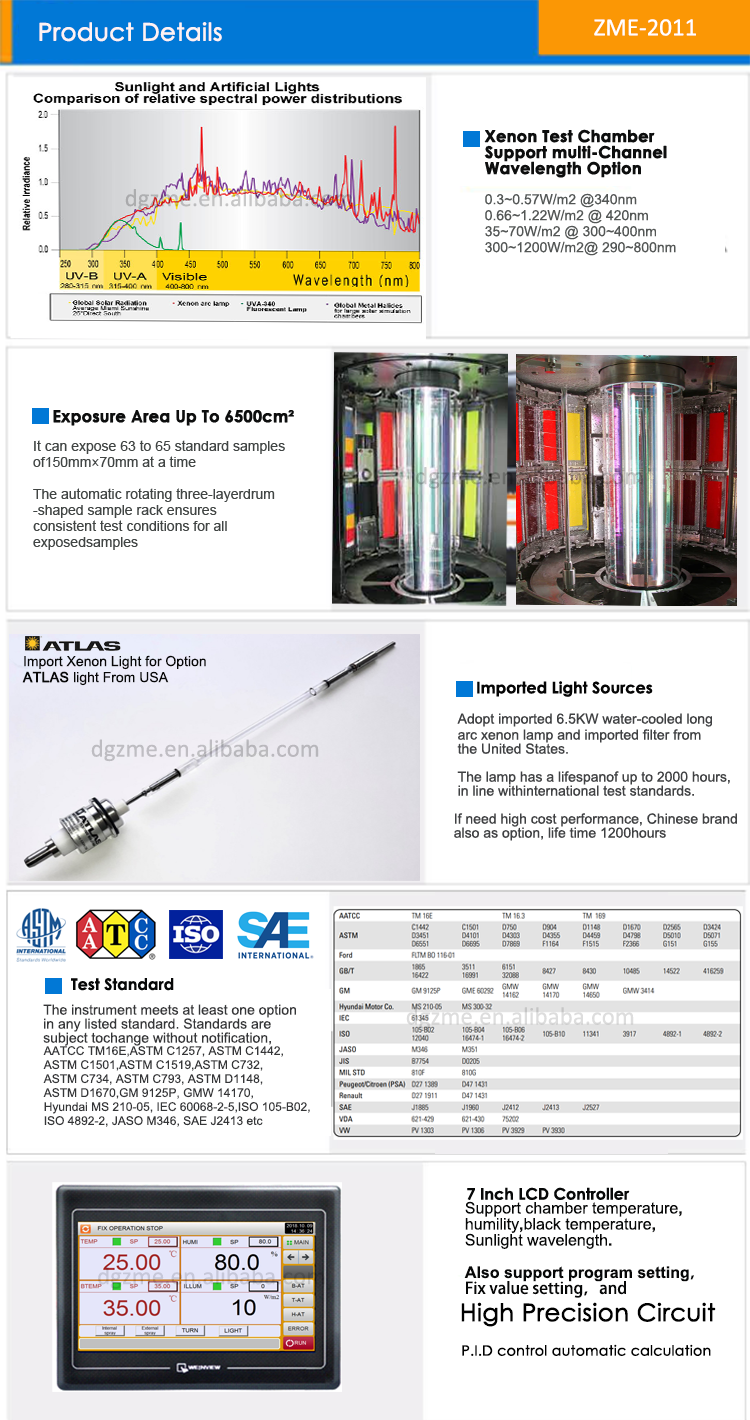

Technical parameter:

| Model | HZ-2011 Xenon Test Chamber | |

| Testing room D×W×H | 500*600*500mm | |

| Index | Temperature range | RT+10°C~80°C |

| Humidity range | 65~98%R·H | |

| Spray time | 1~9999min, adjustable | |

| Spray cycle | 1-240min, interval adjustable | |

| Spectral wavelength | 290nm~800nm (60w/m2) | |

| Light source | Xenon lamp (air-cooled) | |

| Xenon lamp power | 1kw, 6kw (longevity: 1600H) | |

| Temperature and humidity control | Time controller | Import controller from Moeller |

| Accurate range | Temperature: ±0.1°C / humidity: ±0.1°CR·H | |

| Sensor | Platinum resistance Pt100Ω/mv | |

| Heating system | Independent system, nickel chromium alloy electric heating type heater | |

| Humidity system | Stainless steel, external Isolated humidifier | |

| Blackboard temperature | Bimetal thermometer blackboard 55°C~75°C | |

| Water supply | Humidification water supply with automatic control, xenon lamp cooled by water recycling | |

| Temperature controller | Import controller | |

| Humidity | Irradiation: 30%~65%RH darkly: up to 90%RH | |

| Cycle system | Low-noise air-conditioning-type motors, multi-leaf-type centrifugal wind wheel | |

| Material | Outside material | Advanced spray color plate /SUS304 stainless steel |

| Inside material | SUS304 stainless steel | |

| Sample holder material | SUS304 stainless steel | |

| Insulation | High and low temperature aging of silicone rubber | |

| Standard | A set of radiation-proof glass window, dynamic testing sample shelf 1, xenon lamp tube 2 | |

| Protector | Leakage, short circuit, over-temperature, water shortages, motor overheating, over-current protection. | |

| Power | AC380V±10% 50±0.5HZ, Three-phase five-wire system | |

| Environmental temperature | ±5°C~+30°C ≤85%R·H | |