- Product Details

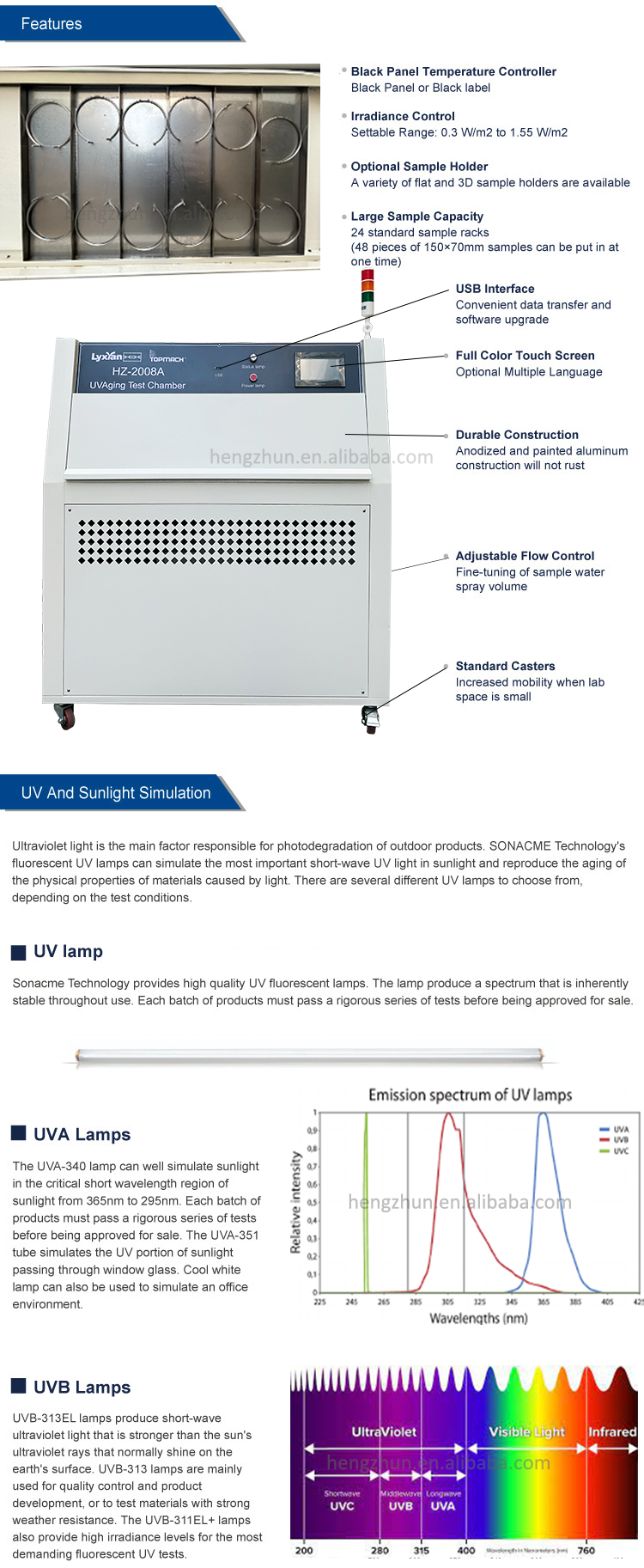

In the UV aging test chamber, the fluorescent UV lamp of the UV lamp can reproduce the effects of sunlight, and the condensation and water spray system can reproduce the effects of rain and dew. The temperature is controllable throughout the test cycle. The typical test cycle is usually UV irradiation at high temperature and dark humid condensation cycle at 100% relative humidity; typical applications are paint coatings, automotive industry, plastic products, wood products, glue, etc.

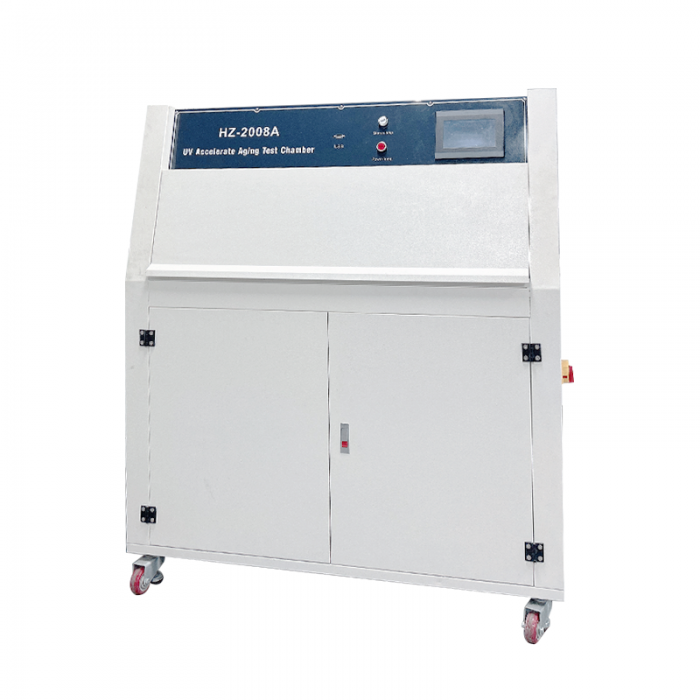

Model | HZ-2008A Reliability Testing-Textile Aging Detection |

Number of lamps | 8 UV lamps, 4 spares ATLAS,UVA340,UVB313,UVC351) |

Recorder | Optional |

Radiometer | Optional |

UV temperature | 50 ℃ -75 ℃ |

Condensation temperature | 40 ℃ -60 ℃ |

Test capacity | 48 pieces (75 x 150 mm) 50 pieces (75 x 150 mm) |

Water volume and consumption | Distilled water per minute Distilled water per day 8 liters |

Volume (length x width x height) | 1320 x 500 x 1500mm |

Weight | 136kg |

Power supply | 1 ψ , 120V/60Hz,16A or 230V/50Hz, 9A,1800W(max) |