- Product Details

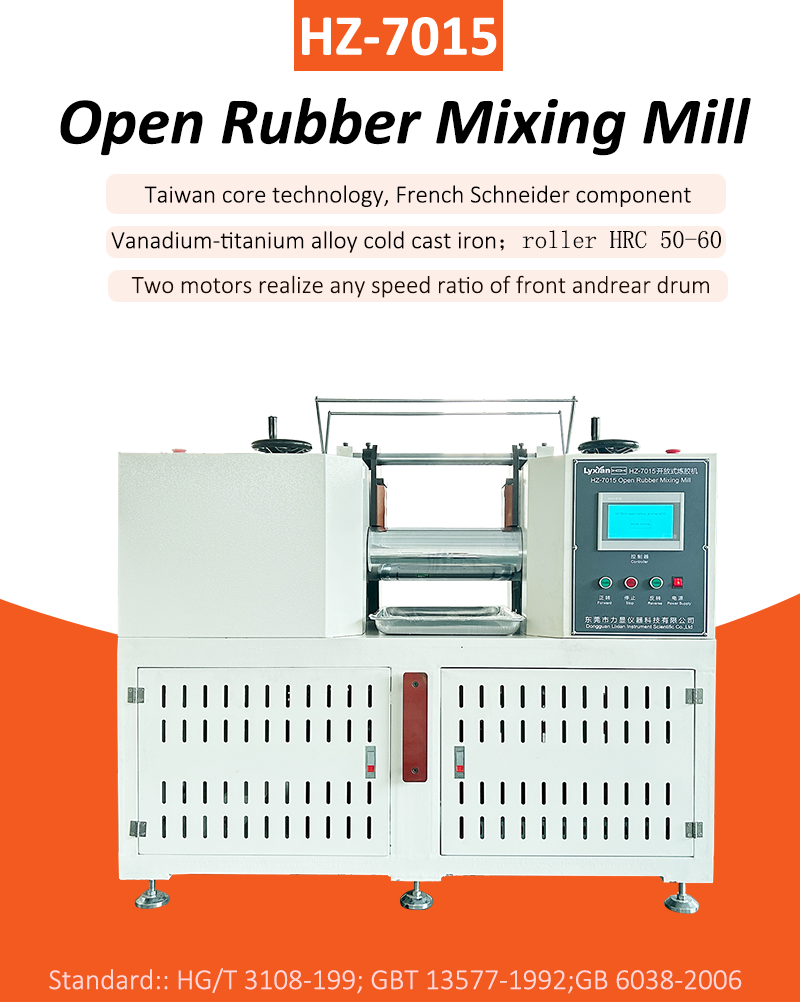

Equipment summary:

Laboratory Small Two Roll Mill manufactured according to GB / T 13577-2006 and GB 20055-2006 design.

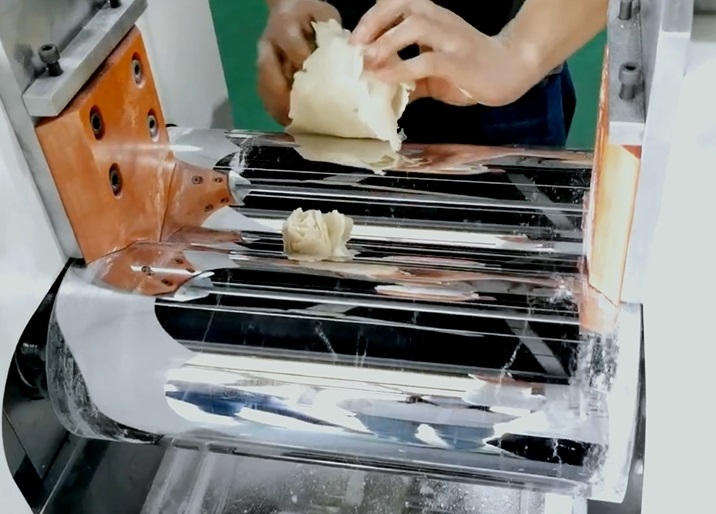

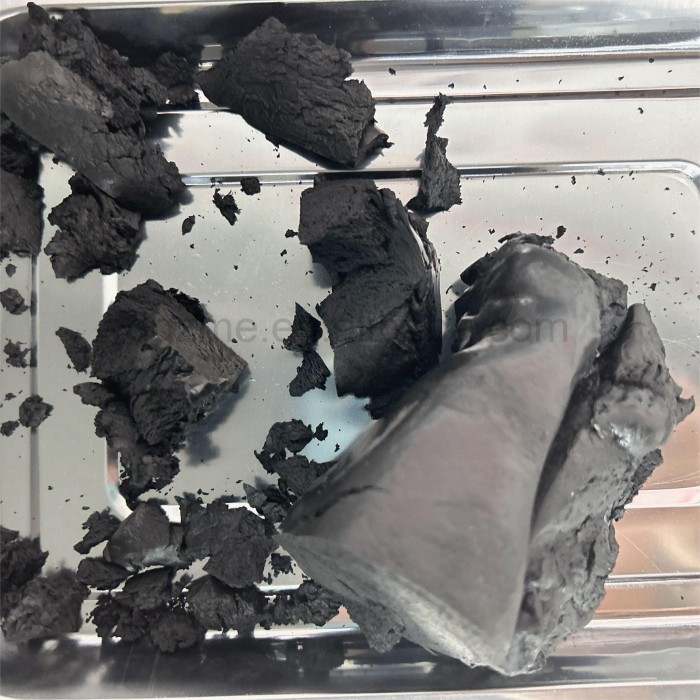

Apply to the compounding of thermoplastics, mastication, or plastic sheeting; rubber thermal refining, tablet,

mastication, mixing.

Applicable industry:

Laboratory Small Two Roll Mill refining presses for thermoplastics compounding, plastic necklace, or plastic sheeting.

Technical parameter:

| Roller Specification | (Diameter×Length) 160×320mm |

| Adjustable gap | 0~10mm |

| Roller speed ratio | 1:1.22 |

| Roll gap | 4mm |

| Reducer type | BWY22—23—5.5KW |

| Motor Type | Y132M2—6 |

| Power | 5.5kW |

| Speed | 960r/min |

| Mixing capacity | 0.2-5kgs |

| Roller temperature | normal temperature~260°C |

| Heating time | normal temperature ~150°C about 15min |

| Heating mode | electric heating |

| Temperature accuracy | ±3.5°C |

| The drum in vitro thermometry | the installation of temperature the meter then extend the line to the thermostat temperature measurement digital display |

| Temperature control | PID controller make in Taiwan |

| Roller revolving speed | fixed speed(24 revolving/min) |

| Roller hardness | HRC 50~60(Made in Taiwan) |

| Roller processing | Polished |

| Baffle material | PTFE material, made of sharp type |

| Safety device | Multiple touch, touch emergency stop, safe operation |

| Power | AC380V,20A |

| Motor power | 20KW |

| Outside dimension | 1100×700×1200mm |

| Weight | about 580kg |

Structure features:

1)The roller are made of high-carbon steel quenching treatment, the surface of hard wear;

lumen of processing, the roll surface temperature uniformity.

2)The machine is equipped with internal heating wire device, roller temperature uniformity.

3)Drive system with worm reducer, compact structure, low noise, high efficiency, long service life.

4)The machine overall base, easy to install.