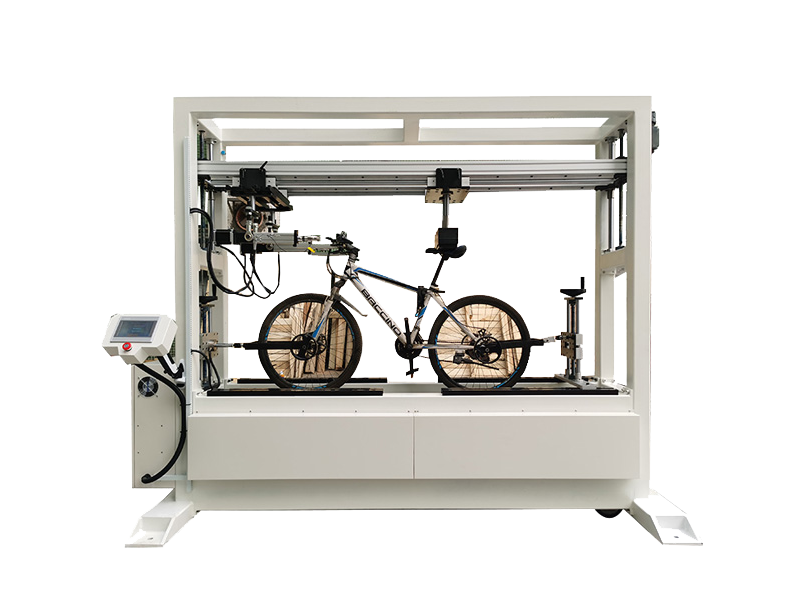

HZ-1364 TB Tire Endurance Test Machine

This is a family of Endurance Test Machines that can be supplied both with vertical and horizontal drum depending on the configuration chosen; with vertical drums we can reach up to 4 tires, while with horizontal drum the machine can test up to 6 tires at the same time. The test machines perform Endurance and/or High-Speed tests on PC, LT, TB, IND, AGRI and OTR tires in compliance with all international standards such as GSO, BIS, UN/ECE, DOT, FMVSS or SAE. The machine can be provided with 1, 2, 4 or 6 test stations.option.