- Product Details

Model HZ-8023 Digital Fabric Water Permeability Tester

Equipment Overview

After the instrument used to measure a variety of waterproof fabric resistance to water, such as canvas, tarps, tent cloth, sheet, rain clothing fabric and geotextile materials.

Standard

1. GB/T4744-1997 "Determination of resistance to water Textiles - Hydrostatic pressure test"

2. 2. FZT01004-91 "coated fabrics Determination of resistance to water penetration - Hydrostatic pressure test"

3. 3. ISO 811-1981 "Determination of Textiles hydrostatic testing water permeability"

4. AATCC 127 Water resistance: Hydrostatic pressure method

5. JIS- L1092 Testing methods for water resistance of textiles

Main Feature

1. This instrument computer control, with five test functions, Park arc nice shape.

2. Using wide screen LCD display, full Chinese menu, simple operation.

3. Selection of high precision pressure sensor, accurate and stable measurement node, and reproducible.

4. With built-in water tank, and a button prompt and effective, fault self-test functions.

Applicable Industry

Used for working closely fabrics, such as the medical textile fabric, canvas, tarps, tent cloth, sheet, non-woven fabric and waterproof clothing fabrics, coated fabrics and other performance testing of water permeability.

Technical Parameters

Model | HZ-8023-5 | HZ-8023-20 | HZ-8023-50 |

Testing range | 500pa-50kpa | 500pa-200kpa | 5kpa-500kpa |

Hydraulic rising rate | 1kpa-20kpa | 1kpa-30kpa | 1kpa-100kpa |

Accuracy | ≤±0.2% | ≤±0.5% | ≤±1% |

Sample chuck area | 100cm2 8cm2 | ||

Unit | Pa | ||

Testing mode | Five (varieties) | ||

Water tank capacity | 1000ml | ||

Dimension | 560x410x500mm(L×W×H) | ||

Weight | 55kg | ||

Power | AC220V, 50Hz | ||

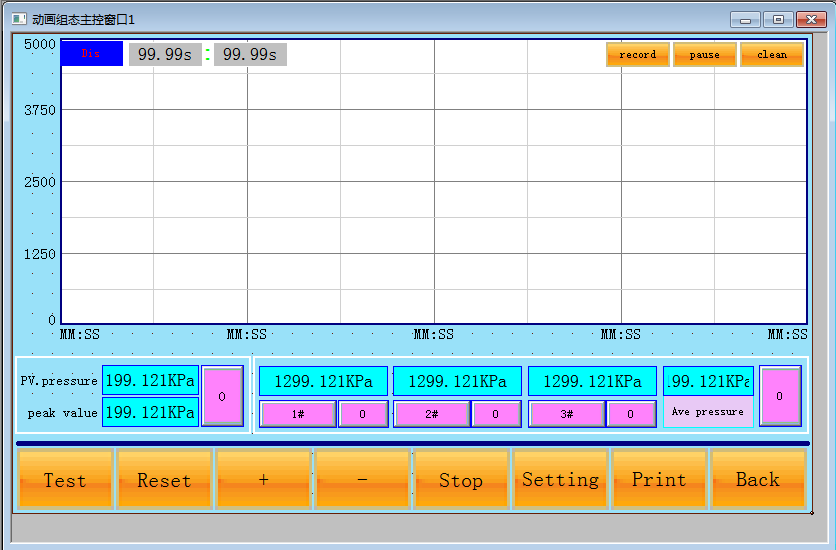

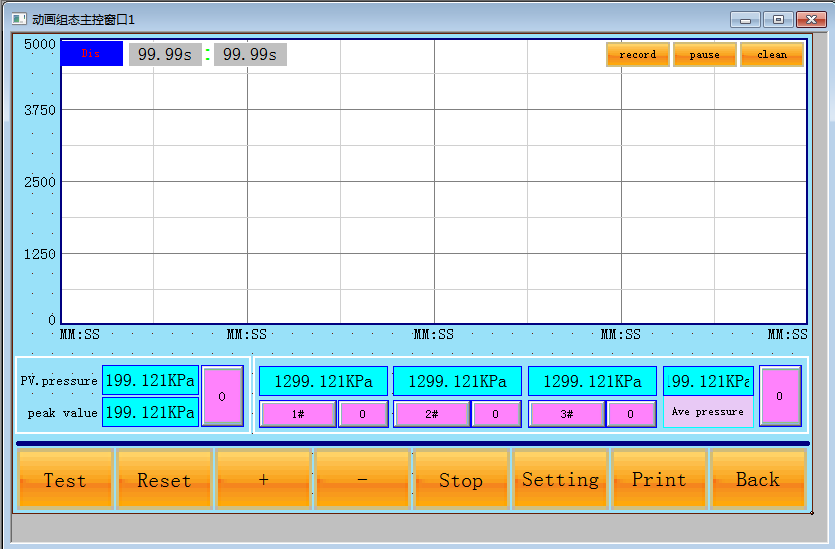

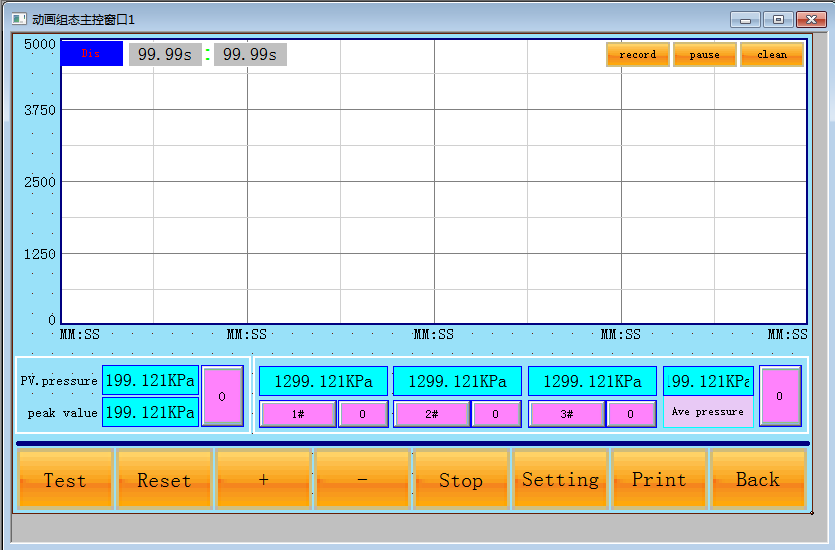

Control Panel Description

Test: Start test button

Reset: Reset button

+ : Long press to start applying water pressure manually, the pump starts to fill water

- : Long press to start manual pressure reduction, the pump starts to pump out and discharge

Stop: Stop button

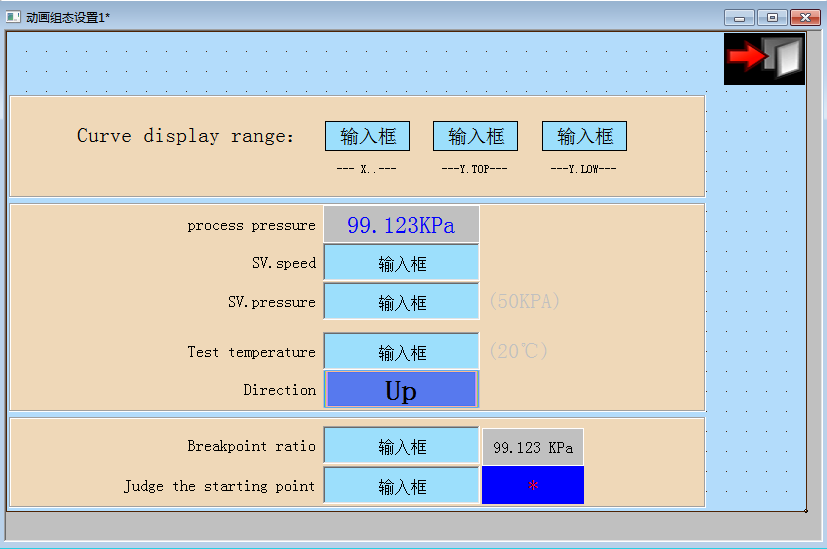

Setting: Set test speed and others

Print: Print test results

Back: Return to the main interface

Experiment Procedure

1. Prepare a water container,fill in water and put water pipe in container, turn on the power and enter the system interface. Press and hold the pressure button to pump water into the test tank to make the water in the test tank almost full.

2. Put the sample to be tested into the fixture and lock it.

3. Click the setting button to set the water inlet speed and keep it at 1 or 6 according to the test requirements

4.Click all the "zero" buttons on the screen to clear all the data, and then start to click the "test" item to carry out the test. When the water seepage point is found, click "1#2#3# seepage point" in order to record the current pressure.

5. After 3 water seepage points appear, press the "Stop" button to stop the test and print the results.

Matters Needing Attention

1. For accuracy of test results, please use deionized water.

2. The instrument must have a good grounding wire

3. After the test, the pressure relief button must be long for pressure relief and drainage before opening the fixture to prevent accidents caused by excessive pressure

4. During water inlet and drainage, pay attention to open or close the valve on the outer surface of the right side of the instrument (the same valve is used for water inlet and drainage)

5. All data must be cleared before the test.

Quality Assurance

1. Quality assurance matters

The free service period of this test machine from the factory date is one year (consumables are not included in the free range, excluding travel expenses).

2. The main certificate of free service

When the service matters are disputed, the "guarantee" issued by our company is mainly used as a certificate.

Therefore: 1. Please keep the <guarantee> properly. If you lose it, you should contact our customer service department for reporting within one month.

3. Guarantee is invalid if it has been altered or our company’s seal has not been added.

4. In the following cases, although within the effective guarantee period, technical or material fees may be charged:

5. Destroyed due to natural disasters.

6. Failure due to user's fault or operation error.

7. Failure to use the power supply voltage as specified causes damage.

8. Self-repair and damage.

9. Lending to others for use and causing malfunctions.

10. Modification by itself causes malfunction.

11. Self-correction causes malfunction.

12. Failure to transfer or transport carelessly.

13. Services in remote areas.

14. Matters needing attention:

For customers outside of Guangdong Province, the transportation and travel expenses of service personnel shall be paid by the customers, regardless of whether they are within the warranty period.