- Product Details

Equipment Overview

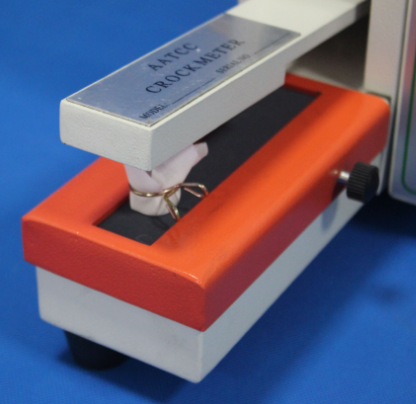

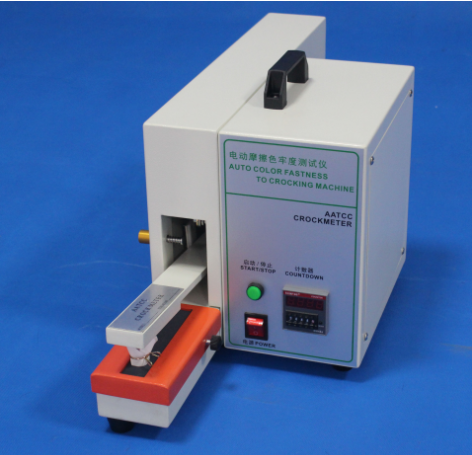

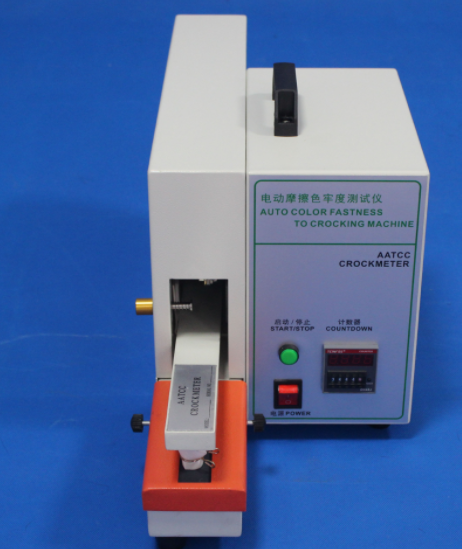

This equipment mainly consists of control system and system of friction, the sample with the sample holder on the base with one end of the paste with sand paper, friction will be wrapped in white cloth placed on the sample, the friction after the specified number, observe the specimen card compared with ashes on the evaluation of white cotton stick color degree, the stability of the dyed or surface coating on the sample of the fabric to judge, and provide reference data for evaluation and selection of materials.This machine is suitable for yarn, yarn-dyed, printing and dyeing and all kinds of fabrics on or inside toys.

Corresponding Standard

1. BS 1006 D02

2. ISO 105X12/D02

3. AATCC 8/165 "

Applicable Industry

This instrument applies to textiles, knitted fabrics, leather, rubber,power of metal plates, printing and other industries.

Technical Parameter

Model | HZ-8027C |

Friction head pressure | 9N(AATCC standard) |

Friction head diameter | ∮16mm |

The number of crank rotation | 60±1rpm/min |

The number of controlled reciprocating | 99 times |

Friction head trip | 104/100mm adjustable(AATCC standard) |

Maximum thickness of the sample | 25*19mm Wet and dry friction |

Motor power | 220V 50HZ |

Dimension | 860*320*265mm |

User Operation

1. The instrument must be placed on a stable table before use.

2. Do not operate the machine in use;

3. Select the corresponding power voltage, do not be too high, to avoid burning the device;

4. In case of any abnormality of the instrument, please contact the institute for timely treatment;

The machine must have a good ventilated environment when it works.

6. Key mechanical components, due to the large operating load, please timely add lubricating oil to the mechanical part;

7. After each test, clean the machine and keep it clean;

8. Please wipe the control box with dry cloth instead of wet cloth

Steps

1.Sample preparation

1.1 The sample and the standard friction cloth should be moistened in a constant temperature and humidity environment

1.2 When the sample has multiple colors, all colors should be rubbed.

1.3 If the area of each color is large enough, it shall be sampled separately.

1.4. Cut the sample and make dry friction and wet friction respectively, and ensure that the friction reaches all colors.

1.5 If the positive and negative sides of the sample are made of different materials and colors, both the positive and negative sides should be tested for color fastness to rubbing.

1.6 Dry and wet rubbing fastness should not be repeated in the same part of the sample.

2.Dry Friction

2.1. Place the sample on the friction instrument paved with sandpaper, make the length direction of the sample consistent with the running direction of the instrument, fix the sample on the pressing plate, and the clamping sample should be smooth.

2.2 Fix the small white cloth of the standard friction on the friction head, clamp it with the spring, and put the friction head on the sample lightly

2.3. The sample shall be free from sliding or wrinkling during friction;

2.4. Put the friction head on the sample.Turn on the POWER and turn on the POWER key.Set test times.

2.5 Press START to START the test.When the number of tests reaches the set value, the instrument will stop automatically

2.6 Remove the standard rubbing white cotton cloth and compare the grading with the colorimetric card.

3.Wet Friction

3.1. Completely soak the standard friction cloth in distilled water;

3.2. After removal, squeeze it in the filter paper to make it have a certain water content;

3.3 The remaining steps are the same as the above dry friction test steps;

4. Result Processing

4.1 Before grading, use clear tape to gently remove loose fluff from the white cloth.

4.2. Apply three layers of unused friction white cloth under the friction white cloth to be evaluated, and evaluate the stain grade of friction small white cloth by referring to the standard stain gray card.

5. Test Report

5.1 standard reporting method

5.Report dry and wet friction results respectively.