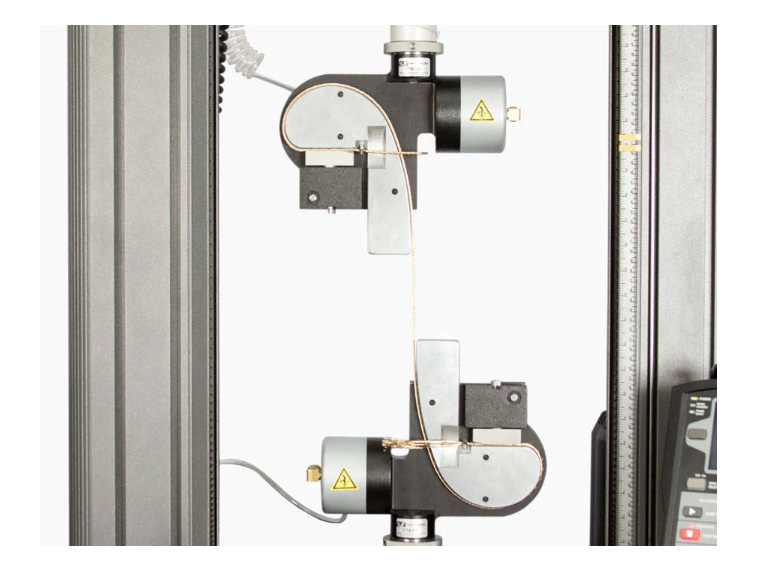

There are mechanical forces acting on the enameled wire, such as tension, friction, and bending torque during winding; friction during the wire embedding process; inter-turn friction caused by vibration during operation.

Compliance with other standards

Lixian Global Services is uniquely positioned to meet the calibration and verification needs of the magnet wire industry and help your lab achieve compliance. Lixian’s calibration lab complies with GB/T5013.4-2008, ASTM D1351-2014, GB/T5013.5-2008, ASTM D470-2013,GB/T2951.11-2008 and other international standards, and is familiar with the standards your lab follows, so we can be your partner to help you understand the calibration requirements that support your quality management system.