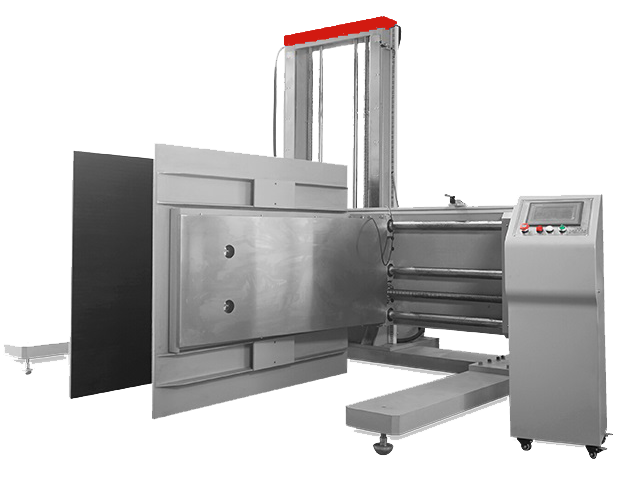

- Product Details

Packaging Clamping Force Testing Machine simulates the process the schnabel car discharge the package, during this process, the clamping force of the both boards will affect the package and cargo. And this test is to evaluate the resistance property of the package toward this clamping force.

Meet standard: ISTA 3E, 3J & ISTA 6 (inclined impact test)

Technical parameter:

Model | HZ-6064 |

Max.Force | 1KN, 2KN,5KN,10KN,20KN |

Maximum specimen weight | 1500kg (can be customized) |

Load cell | 4 load cell for highest accuracy |

Control system | Touch screen controller |

Motor | AC servo motor /DC variable speed drive system, high-precision mechanical ball screw rod |

Force reading | kgf, Ibf, N, KN, T etc |

Load cell Resolution | 1/250,000 |

Load Precision | within ±0.25% |

Parallelism of Platens | Parallel within ±2.5mm |

Clamping plate size | 1500*1500MM |

Clamping plate adjustable height | 0~1000mm |

Clamping plate adjustable width | 200~2000mm |

Base plate dimension | 1500X1500mm OR CUSTOMIZE |

Test speed | Up and down, 0.25-2.5mm/sec (according ISTA 6- SAMS CLUB) |

Data display | Load, displacement, speed, loading rate and elapsed time |

Function | The clamp can be up and down |

Safety features | E-Stop Over-load protection Upper and lower limit switches Load sensor with automatic retreat |

Clamping Force Testing Method Of Large Products

l Before placing the packaged product between platens, verify that the clamp force using the clamp indicator. The indicator should be placed between the axes of the platen articulation points approximately 1/2 way up the platens.

l Each time the product is clamped, the force should be applied for a minimum of 15 seconds and not to exceed 1 minute.

l Apply the clamp force on the sample with the platens resting on the floor and the front edge of the platens flush with the front of the package (see flush platen photo 4). If the package is too large for the clamps to be flush to front edge (i.e., large refrigerator, tractor etc.), clamp as close to the edge as possible.

l Clamp the product a total of 10 times in the flush orientation.

l Apply the clamp force on the packaged product with the platens in a 6×6 inch(15.2x15.2cm) offset position(see fig 5 ). Both the horizontal and vertical offset dimensions are measured at the front bottom corner of the platen. If the package is too large for the clamp to be positioned 6-inches from the front edge (i.e., large refrigerator, tractor etc.), clamp as close to this position as possible.

l Clamp the product a total of 10 times with the clamp in the 6 x6 inch offset position.

l Repeat step 5.2.5 except with a 2 x6 inch offset clamp position. The 2 x6 inch offset is similar to the 6 x6 inch offset except the platens are oriented such that they are 2-inches from the floor and 6-inches back from the package’s front edge. If the package is too large for the clamps to be positioned 2-inches from the front edge (i.e., large refrigerator, tractor etc.), clamp as close to this position as possible.

l Repeat flush and offset clamping on all other sides of the product that are indicated in the handling graphics as acceptable for clamp handling.

l According to verdict standards, if there is one item failed the test, then put forward the “Test Failure Handling Sheet