- Product Details

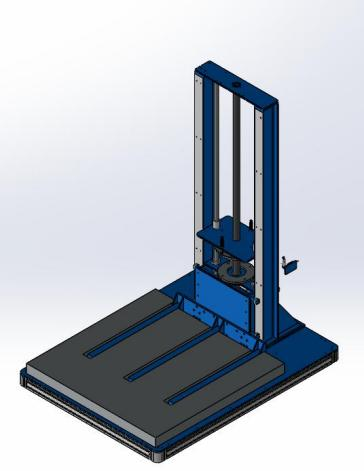

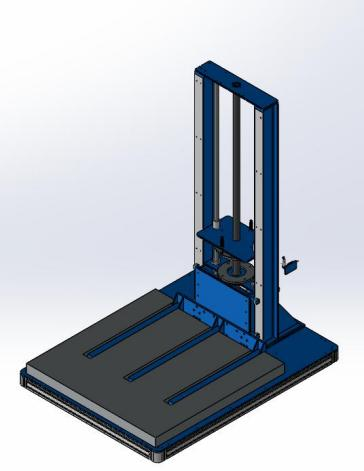

Package Carton Zero Drop Testing Machine Equipment HZ-6002C

Equipment Overview

The zero drop tester is mainly used to assess the impact of packages during actual transportation and loading and unloading, and assess the impact strength and packaging design during handling. The zero drop tester is mainly used for large package drop test. The machine consists of a E" fork that moves move down and the test product is balanced by the test requirements (faces, edges, angle tests). During the test, the support arm moves downward at high speed, and the test product fell to the bottom glue with the "E" -fork, flat in the bottom plate under the action of the efficient damper. In theory, the zero drop tester can perform the drop test from the zero height range. The drop height is set through the LCD controller and automatically performs the drop test according to the set height.

Control principle: reasonable design for free fall, edges, angle and surface design

Technical parameter:

Model | HZ-6002C |

Maximum weight of the test specimen | 0—300Kg(Can be customize) |

Drop height | 0—1500 mm |

Maximum test size | 1500×1500×1500mm |

Test aspects | Face, edge and angle |

Working power supply | 380V/50HZ |

Drive mode | Motor drive |

Protector | Induction protective devices equipped with upper and lower devices |

Impact plate material | 45 # steel, solid steel plate |

Height display | Touch - screen control |

Drop height identification | Use of scale identification |

Arm - support structure | 45 # steel, square welding |

Driving mode | Taiwan imported straight - line slide block and copper guide sleeve, 45 # steel |

Accelerator | Pneumatic type |

Drop mode | Electromagnetic and pneumatic integrated coordination |

Weight | About 1500KG |

Power | 5KW |