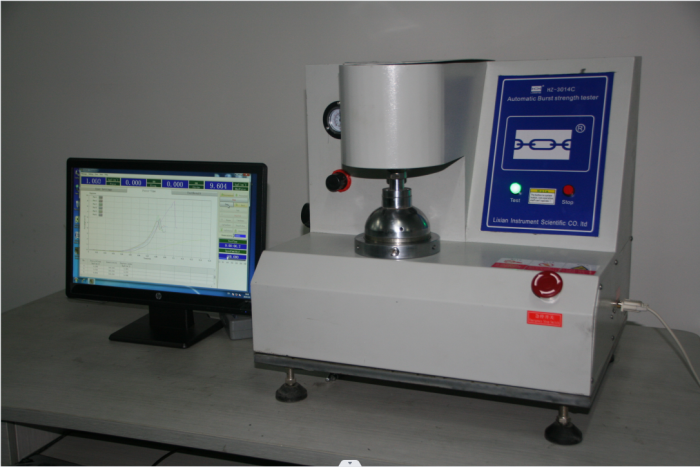

- Product Details

Equipment Overview

This machine is suitable for the rupture strength test of base paper, cardboard, single-layer or multi-layer corrugated, suitable for paper making, color printing and packaging, food, electronics, electrical appliances, and other industries. It is started by one button and automatically detects the whole process. It adopts the measurement and control method with single-chip microcomputer as the core, so as to realize all the digitization, micro computerization and intelligence of detection, control and data processing. Various technical parameters and performance indicators are in line with ISO2758 "Determination of Paper Bursting Strength", QB/T "Paper and Paperboard Bursting Strength" and GB454 "Determination of Paper Bursting Strength" and other standards and requirements.

The instrument is easy to operate, reliable in performance, and advanced in technology. It is an indispensable ideal equipment for scientific research units, paper manufacturers, packaging industries, and quality inspection departments.

Operation method

1) This machine is a fully automatic testing machine, as long as the sample is put in, it can start and automatically complete the test with one button, automatic return and automatic calculation, and save the test data.

2) Using signal transmission pressure, the maximum rupture strength value is automatically retained when the sample ruptures.

3) Control method: Computer controlled English control.

Standard

JIS-L1004、P8131、P8112、ASTM-D2210、TAPPI T403、ISO2759、GB/T 1539、GB/T 454、

GB/T 465.1、GB/T6545、ISO2759、GB1539、QB/T1057 etc.

Features

1. The display adopts large-screen Chinese and English LCD, which can display more information;

2. The data report ca n be automatically printed out;

n be automatically printed out;

3. With 8 control keys (5 function keys, 3 multiplex keys), easy to operate;

4. Power units: N, kN, kgf, gf, lbf;

5. Stress unit: Pa, kPa, MPa, kgf/cm2, lbf /in2;

6. Length (area) unit: mm, cm, in;

7. Display function: at the end of the test, the maximum force during the test can be automatically displayed and memorized;

8. Save output: can record up to 40 groups test results.

Technical Parameters

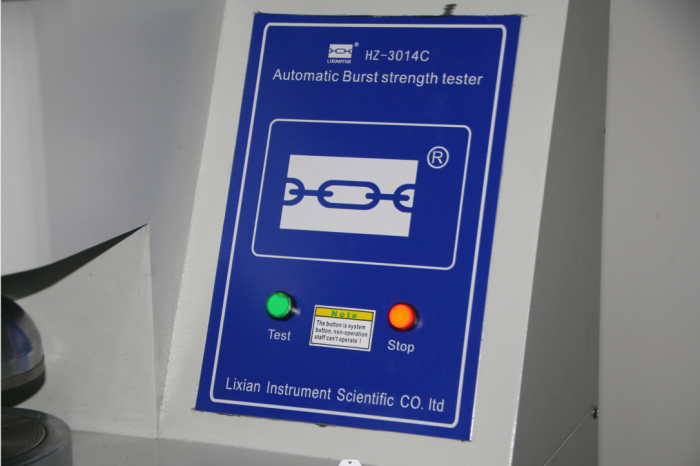

Model | HZ-3014C |

Display (control) mode: | Touch screen control,Computer controlled is option |

Measurement range | 0~50 kg/cm² |

Resolution | 0.01kPa |

Indication accuracy | Indication error ±0.5%, indication changes ±0.5% |

Pressure (oil feeding) speed | (175±15) ml/min |

Height of film resistance bump | 10mm 18mm |

Resistance value of film | (170~220)kPa,(250~350)kPa |

Upper platen | Φ 31.50mm , ±0.05 |

Down platen | Φ 31.50mm , ±0.05 |

The clamping force of the sample | (400~1200)kPa |

Test system tightness | Pressure drop < 10%Pmax within 1 min |

Test unit | kpa、psi (Lbf/in^2)、kgf/cm^2, can be exchanged |

Printing function | high speed thermal printer |

Printing content | serial number, maximum, minimum, peak value, average value, etc. |

Hydraulic oil | silicone oil |

Discharge capacity of air compressor | (0.02 ~ 0.3) m3/min |

Rated pressure | (0.6 ~ 0.7) MPa |

Dimensions | 370*400*550mm |

Working power supply | AC220V 50HZ |

Power | 120 w |

Air source | with air compressor (customer-provided, optional) |

Accessories | Wrench: 1 piece special silicone oil : 1 bottle Correction sheet : 10 pieces Rubber film: 2 pieces English manual: 1piece |