- Product Details

HZ-9701B Belt Drive Balancing Machine

Overview

HZ-9701B is a ring-driven balancing machine, which adopts ring-belt transmission to ensure the balance quality and accuracy of the workpiece. The ring-belt transmission is convenient to load and unload, and the work efficiency is high. It is widely used in the balance correction of rotating body workpieces such as motor rotors, power tool machine tool spindles, and ventilation equipment.

Note: Ring belt dragging-is the use of rubber endless belt or silk woven endless belt, the rotor is driven by the motor pulley, so the ring belt dragging requires the rotor surface to have a smooth cylindrical surface, and the balance accuracy is high.

Application

It is mainly a hard-bearing balancing machine that combines high-precision mechanical parts and advanced electrical parts. This series of products is one of the general horizontal belt drive balancing machines developed, designed and manufactured by our company based on core technology at home and abroad. , Is currently the most advanced model in the world, applied to all kinds of rotating workpieces, such as: medium-sized motors, turbocharger rotors, machine tool spindles, crankshafts, water pump rotors, compressor rotors, various rubber roller rotors, small and medium fan impeller rotors , Building steel bar straightening machine and other industries.

This machine adopts a belt transmission device, which has the advantages of high precision, high efficiency, convenient operation, intuitive display, rapid measurement, stable performance, and the use of frequency conversion speed regulation device to control the speed.

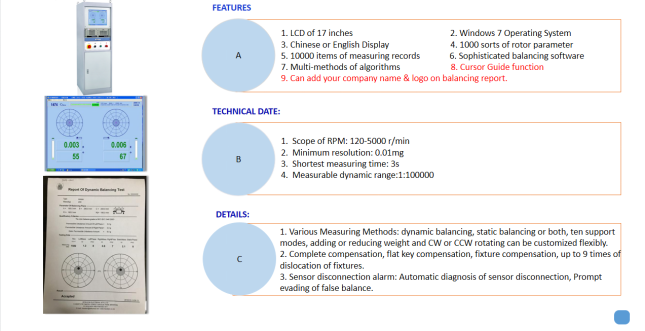

Features

1. The professionally designed swing frame can effectively transmit mechanical force, is sturdy and reliable, has low vibration resistance and good rigidity;

2. High sensitivity sensor, good linearity, durable and reliable;

3. Permanent calibration measurement principle, high accuracy, allowing extremely high initial imbalance;

4. Equipped with special fixtures, with higher accuracy and easier clamping;

5. Advanced electrical measurement system, friendly man-machine interface, complete functions

Control System

The first step is that we want to do the motor rotor balance on the precise measurement station, operation, according to the sensor capture, through the main board, filter board, A / D acquisition card, passive floor, for the conversion, selection of the motor rotor vibration signal, calculation, so as to measure the phase and size.

Then the data is displayed on the display screen, the dynamic balance machine detection system is mainly through the program input original data, in the internal calculation process, according to the transmission of data between each electronic component, and then appear with the graphical interface, so that we can normally identify the effect. The data information in the dynamic balance machine is coordinated and controlled through the data bus and the control bus

Purpose

An unbalanced rotor generates a pressure on its supporting structure and the rotor itself during its rotation, and causes vibration. Therefore, the dynamic balance of the rotor is very necessary. The balancing machine is to check the dynamic balance of the rotor in the rotating state. The function of dynamic balance is:

● Improve the quality of the rotor and its components

● Reduce noise

● Reduce vibration

● Improve the trial life of supporting parts (bearings)

● Reduce user discomfort

● Reduce the power consumption of the product

Technical Parameters

Model | HZ-9701B-50 | HZ-9701B-100 | HZ-9701B-300 | HZ-9701B-500 |

Max Mass of Workpiece(kg) | 50 | 100 | 300 | 500 |

Max Diameter of Workpiece | Ø1000mm | Ø1200mm | Ø1500mm | |

Distance Between Two Support Bearings (mm) | 110-1800 | |||

V-Shape Journal Diameter Scope of Workpiece (mm) | Ø10 ~ Ø140 ( Equip SKF bearing) | Ø10~ Ø180 ( Equip SKF bearing) | ||

Diameter Scope of Driving Belt (mm) | Ø 20~ Ø 450 | Ø 80~Ø 700 | ||

Balance speed (r/min) (when dragging workpiece diameter Ø100) | ~1900,frequency conversion stepless speed regulation | |||

Motor Power (kw) | 1.5 (Inverter motor) | 3 (Invertermotor) | 3.7 (Inverter motor) | |

The smallest achievable residual unbalance (g.mm/min) | emar≤0.3 | |||

Unbalance reduction rate (%) | URR≥90% | |||

Measuring system | Microcomputer digital electrical measurement system (optional computer measurement system) | |||

Note: The technical parameters of the above series of balancing machines are for reference only. The specific parameters and quotations need to be determined according to the actual situation of the rotor of the user's workpiece, and can also be customized. | ||||