- Product Details

Specification:

Mattress Rolling Tester is used to simulate human motion to assess the durability of the mattress. Mattress Rolling Machine

Product description:

The Mattress Rolling Machine has been manufactured to determine the durability of any type of mattress and box spring unit, regardless of the materials of construction, by simulating long-term use conditions. It consists of a weighted roller which moves width ways across a test mattress to simulate body movement.The length of stroke to which the Roller moves is very easily adjusted, by sliding the stroke adjustor left or right, to suit the relevant mattress under test.Unloading and loading of the Roller onto the test mattress is done easily via a motor driven lifting assembly.

Main technical parameters:

Test purpose: Using a horizontal hexagonal wooden drum roll or cylinder (both ends of the diameter of 250 mm, the middle part of the 300 mm, rolling back and forth on the mattress , simulate human motion to assess the durability of the mattress.)

According to different mattress to adjust the rolling stroke(adjust the limit switch position)

Low coefficient of friction guide, ensure full drum weight on the mattress.

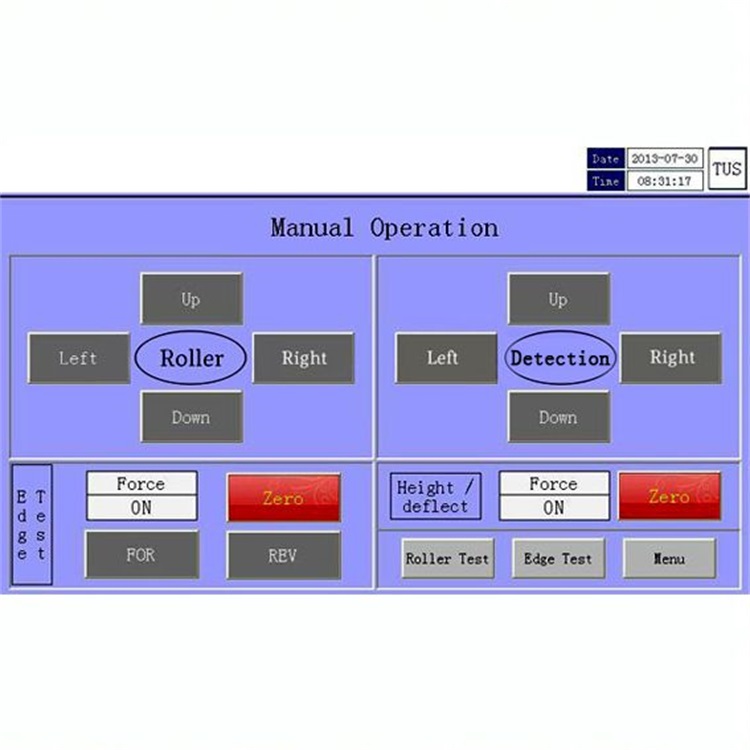

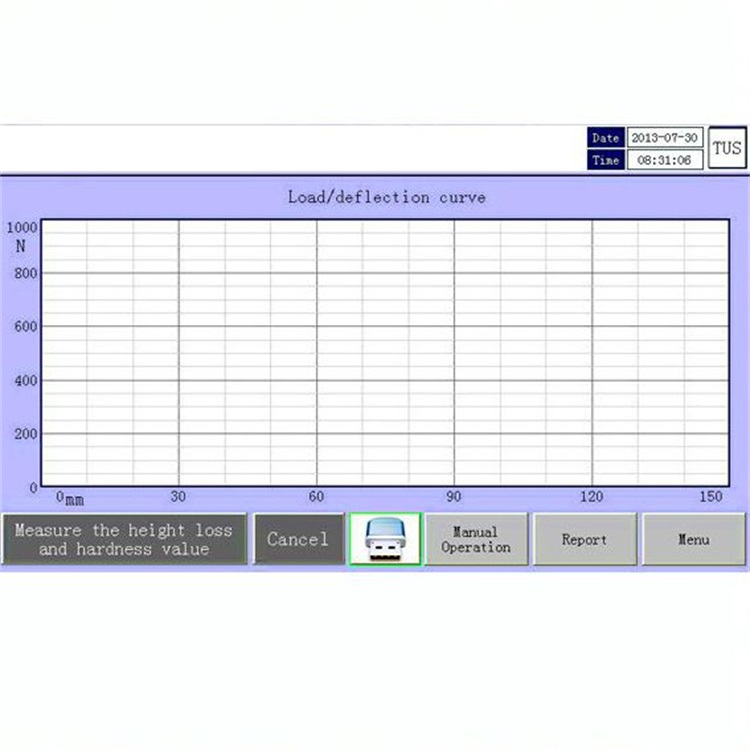

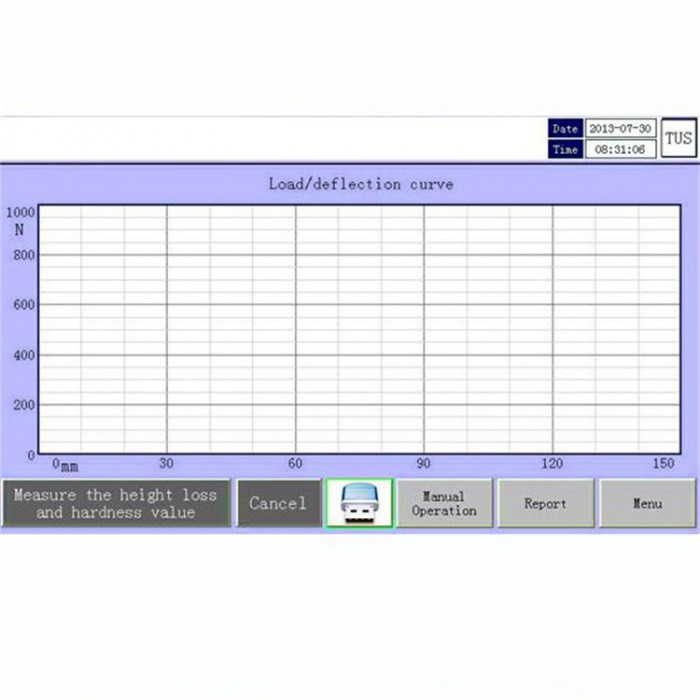

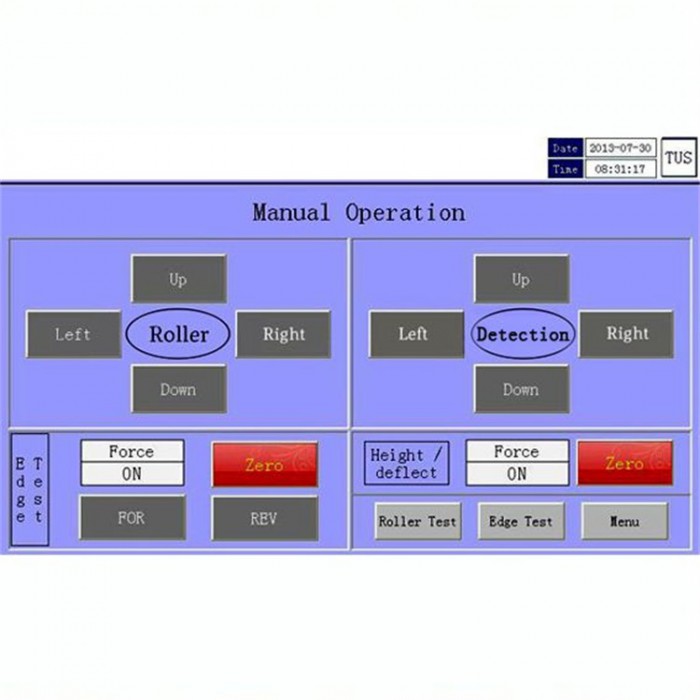

The PLC controller provides easy control and setting.

Test standard: | ASTM F1566, EN1957 |

Hexagonal wood barrel: | 240±10Lb(109±4.5kg), Length 36±3in(915±75mm) |

Cylinder wood barrel: | 140kg, length 1000mm(Each wood barrel coated and overlapped.) |

Maximum size of mattress: | 2.2m×2.2m |

Test speed: | 0-20r/min |

Accessories: | One Hexagonal and Cylinder wood barrel each. |

Machine size(L×W×H): | about 3500×3200×2800mm |

Weight: | about 700kg |

Mattress Rolling Machine main components:

1. Motor: Taiwan's Teco Motor with reducer of Italy

2. Speed adjustment: Taiwan's "Ed Force" drive

3. Guide bearing: Import from Japan.

4. Rack: aluminum body and steel

5. Control elements: Imported.