Tensile Testing of Surgical Sutures

METHODS AND EQUIPMENT FOR SUTURE TESTING

Sutures are some the most commonly used hospital consumables. Used in most surgeries and wound closures to join body tissues, sutures are typically either absorbable, meaning they will naturally decompose after the wound has healed, or non-absorbable and need to be removed by a physician. They can also be coated or non-coated, with a coating typically exhibiting antibiotic properties to reduce the chances of infection.

It is extremely important that suture manufacturers are confident in the tensile strength of their products. Sutures are first subjected to tensile strength during the application process and then need to maintain near constant tension on tissues while the healing process occurs. The risks of failure are high: sutures used internally can cause internal bleeding or other fatal complications should they break or become too slack.

Tensile properties can change depending on the material, size, and coating of the suture. Though the ASTM and ISO organizations do not have a standard specifically dedicated to the testing of sutures, biomedical manufacturers still perform tensile tests in order to obtain a full mechanical profile. Tensile tests are typically performed on the suture with and without a knot to mimic real world use.

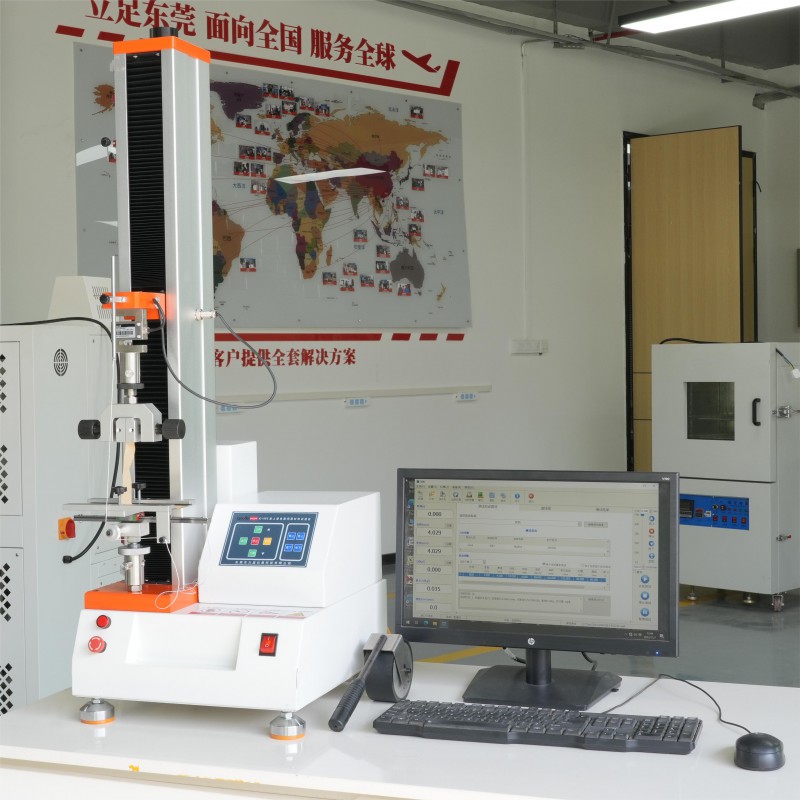

Materials Testing Systems

Most biomedical testing is performed on single-column materials testing systems such as lixian's HZ-1007E series. While suture testing typically only requires maximum load measurement, more advanced testing systems such as lixian's HZ-1007E series may be a better choice for labs with multiple testing applications. For those labs with high throughput needs, LIXIAN's automated systems can be configured to test sutures as well as many other materials.