The rubber and plastics industry supplies products to many other industries and has a profound impact on the development of the automotive, electronics, white goods and packaging industries. In addition, the pharmaceutical, sports and toy industries are closely linked to the rubber and plastics industry.

Comply with other standards

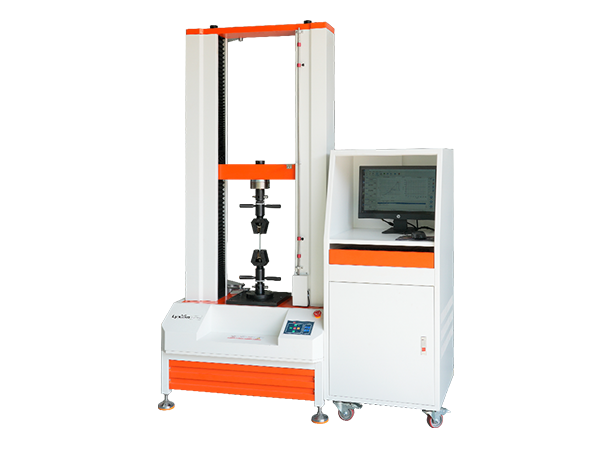

Lixian global service organization is uniquely positioned to meet the calibration and verification needs of the rubber industry, helping you achieve compliance in your laboratory. Lixian's factory-trained field service engineers can also perform certified calibration services with traceability to ensure accurate and reliable test results. Lixian's calibration laboratories meet ISO, ASTM, DIN, GB and other international standard requirements, and are familiar with the standards followed by your laboratory, so we can be your partner to help you understand the calibration requirements that support your quality management system.