- Product Details

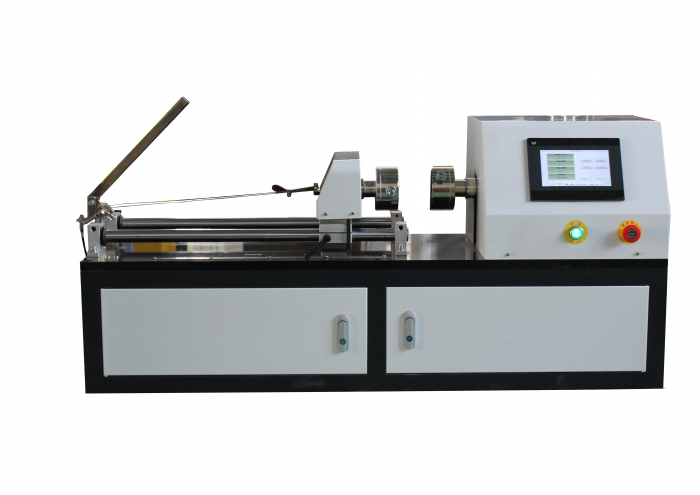

Product Overview:

This machine uses a high-performance AC motor as the power output, and is equipped with a high-precision reduction motor, so that the power can be output smoothly. The motor is driven by a high-reliability, high-stability inverter to improve the smoothness of the machine operation and reduce power consumption. One side of the chuck is fixed to the motor output shaft, and the other side of the chuck is fixed to the movable bearing seat. The movable seat uses a linear bearing with low friction resistance to ensure the straightness of the axial movement. The axial tension is applied by a weight, and the force is applied to the wire through a 10:1 L-type lever.

Compliance with standards:

The metal wire torsion tester is applicable to the People's Republic of China standard GB/T 239.1-2012 "Metallic materials - Wires - Part 1 - Unidirectional torsion test method" and GB/T 239.2-2012 "Metallic materials - Wires - Part 2 - Bidirectional torsion test method", and also applicable to the international standards ISO 7800:2003 "Metallic wire unidirectional torsion test method" and ISO 9649:1990 "Metallic wire bidirectional torsion test method".

This machine is mainly used for mechanical property analysis of metal wires in mechanical laboratories of colleges and universities, scientific research departments, and industrial and mining enterprises. It is also widely used for online detection in production units. The main industries include steel mill high-speed lines, prestressed steel wire factories, quality supervision, scientific research institutes, highway transportation, construction industry, steel wire ropes, wires and cables, copper and copper alloy conductors for electrified railways, copper contact wires, etc.

| Model | HZ-4012A |

| Working mode | Automatic loading |

| Display mode | LCD Chinese menu display |

| Parameters: | |

| Diameter of metal wire that can be clamped | 0.1≤d(D)<1.0 |

| Space between two clamps | 500mm |

| Jaw clamping range | 0.1-1.0mm |

| Clamp hardness | >55HRC |

| Torsion speed | 60、180、300r/min |

| Speed error | <±5% |

| Minimum reading value of the number of turns | 0.1 |

| Test machine dimensions (length*width*height) | 1250×430×600mm |

| Test machine weight (net weight) | 140kg |

| Power supply | AC 220V 50Hz |

| Noise | <50 dB(A) |

| Assembly quality | Assembly quality |

| Packaging and transportation | Packaging and transportation |

Working environment:

(a) In the room temperature range of 10℃–35℃, if there are special requirements, the test temperature should be 23℃±5℃;

(b) Placed on a stable foundation;

(c) In a clean environment with no vibration and strong electromagnetic field interference;

(d) The fluctuation range of the power supply voltage should not exceed ±10% of the rated voltage.