- Product Details

Down beam go up and down by the use of motor reducer, chain drive mechanism, vice screw drive, to achieve tensile, compression of space to adjust. (Hydraulic System Universal Test Machine HZ-003)

Hydraulic System:

The hydraulic oil in the tank through motor drive high-pressure pump into the oil, flows through check, high pressure oil filters, differential pressure valve set, servo valves, into the oil cylinder.Computer control signals to the servo valve, the control and direction of the servo valve opening to control the flow into the cylinder to achieve constant test force, constant displacement control. Through the tubing, pressure tubing through and through oil return valve to tank.

Control system:

Support for tensile, compression, shear, bending and other tests;

Support open editing test, editorial standards and editorial procedures, and to support export import testing, standards and procedures;

Support custom test parameters;

Adopt an open statement in the form of EXCEL, to support user-defined report format;

Safety protection device:

a) When the test force more than 3% of the maximum test force, the overload protection, oil pump motor shut down.

b) When the piston rises to the upper limit position, stroke protection, pump motor shut down.

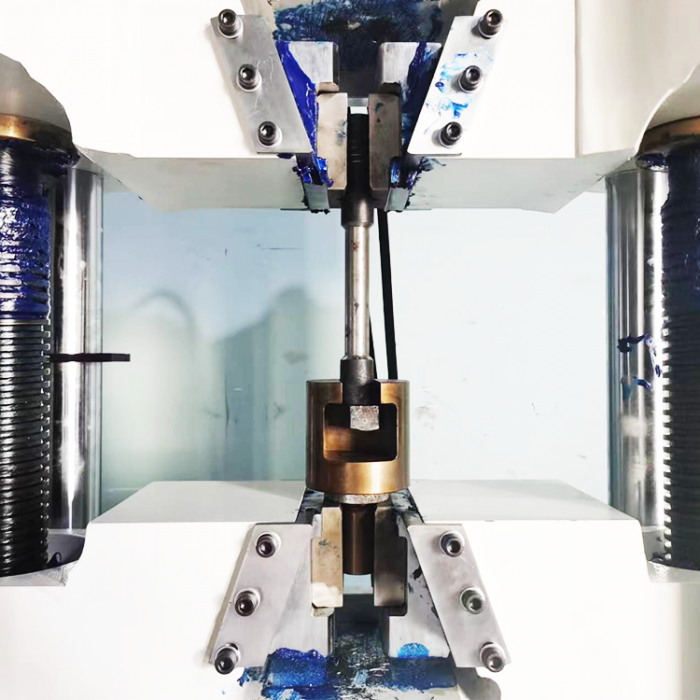

Fixture:

Whole set fixtures include: stretch fixture, compression fixture, bending fixture

Technical specifications:

| Max load KN | 100 | 300 | 600 | 1000 | 1200 | 2400 |

| Test force measuring range KN | 2%-100%FS | |||||

| Test Force showed the relative error | ≤indicating value±1% | |||||

| Test Force Resolution | 0.01kN | |||||

| Displacement measurement resolution mm | 0.01 | |||||

| Deformation measurement accuracy mm | ±0.5%FS | |||||

| Maximum tensile test space mm | 550 | 650 | 750 | 900 | 1000 | |

| Max compression space mm | 380 | 460 | 700 | 900 | ||

| Maximum clamping width of the flat specimen mm | 70 | 75 | 125 | 80 | ||

| Maximum clamping width of the flat specimen(Column number) | 2 | 2/4 | 4 | |||

| Shear specimen diameter mm | 10 | |||||