HZ-9735A Motorcycle Crankshaft Balancing Machine

Description

Application

Used for the unbalance correction of rotating workpieces such as grooved drum shafts of textile machine.

Features

This machine adopts HZ-9735A electronic measurement system, with various measurement methods, dynamic and static balancing, bearing modes are up to 10 kinds, weight addition& removal, CW and CCW rotation can be flexibly customized. It adopts multiple calibration coefficient combinations, automatically adjusts system sensitivity, and shifts without jumps, software and hardware dual filtering, data compression, the measurement is more stable.

parameter

| Technical data at a glance |

HZ-9735A |

| Max Mass of Workpiece(kg) |

50 |

| Max Diameter of Workpiece (mm) |

Φ700 |

| Distance Between Two Support Bearings (mm) |

80~700 |

| Journal Diameter Scope of Workpiece (mm) |

Φ 8~755) |

| Diameter Scope of Driving Belt (mm) |

Φ18~200 |

| Rotational Speed when the Diameter of Driving Belt is 100mm (r/min) |

700,10501) |

| Motor Power (kw) |

0.752) |

| Length of Bed (mm) |

|

| Min Achievable Residual Unbalance Amount (emar) |

≤0.15g· mm/kg |

| |

|

1) Stepless speed regulation

2) Frequency conversion

3) Can add to 75-180

4) Can add to 120-240

5) Can add to 75-140

| Customized support |

OEM |

| Place of Origin |

Dongguan, China |

| Brand Name |

LianXian |

| Model Number |

HZ-9735A |

| output |

0.23KW DC Stepless speed regulation |

| length |

900mm |

| width |

700mm |

| height |

1150mm |

| gross weight |

260kg |

| number of packing |

1pcs |

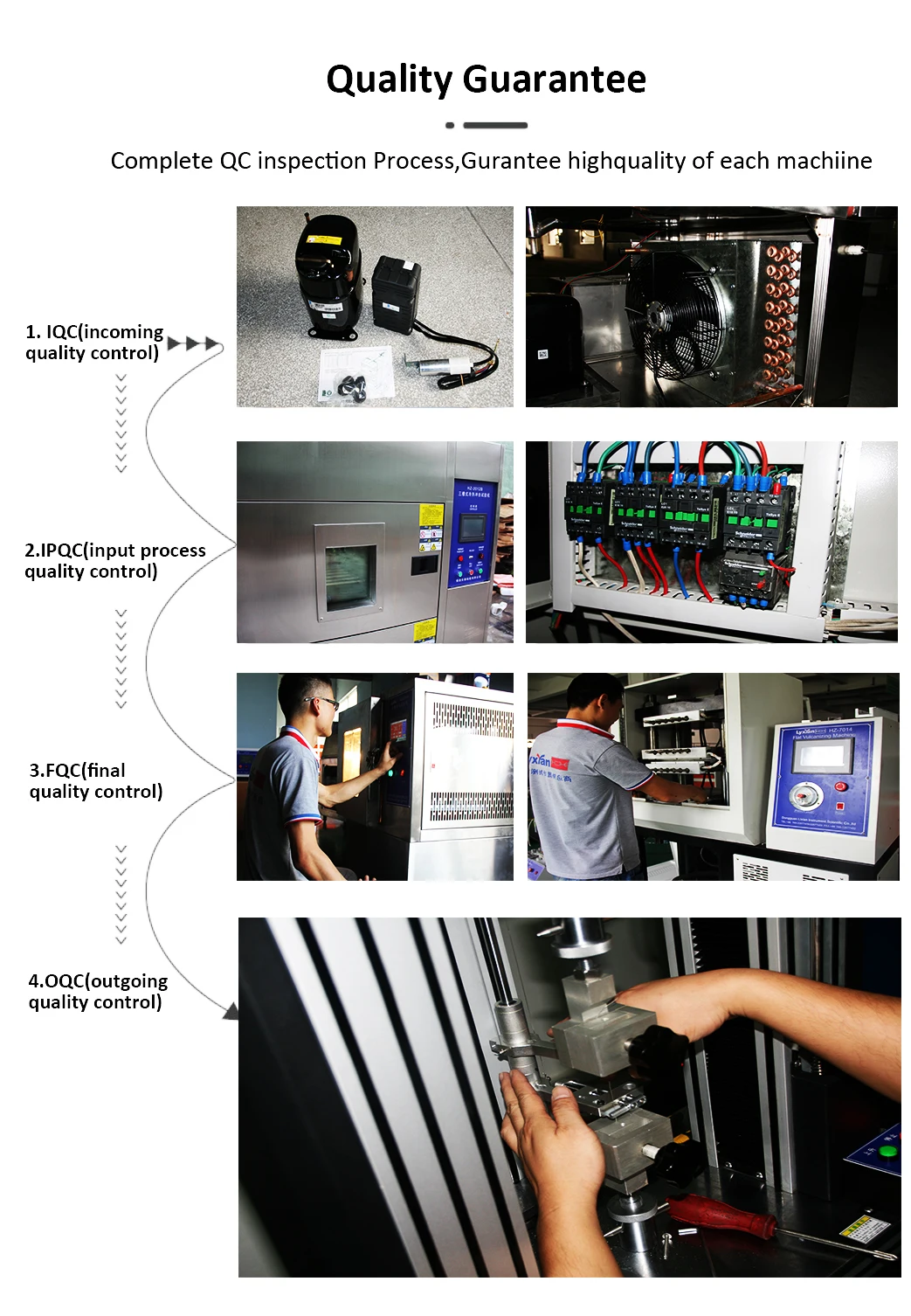

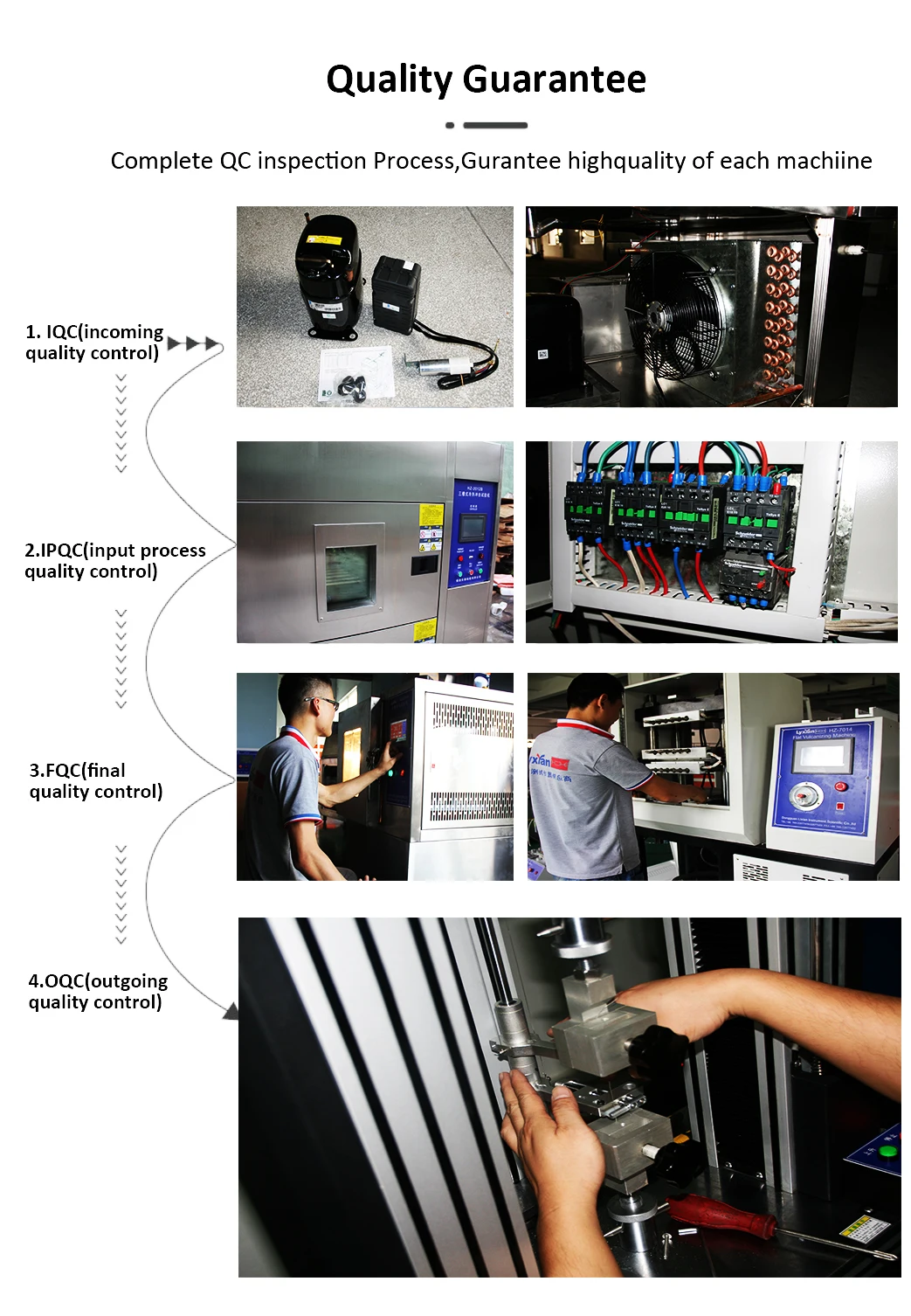

Dongguan ZME Machine Trading Co.,td is one of the leading manufacturers of advanced testing instruments, founded on 2000, located in Dongguan, Guangdong province in China. Dongguan ZME Machine Trading Co.,td located in Dongguan city, covers an area of 6000 square meters, take the lead in introducing the CNC processing center and NC lathe and other advanced equipment in 2010. Carried on several listed company lab, quality institutions, Tsinghua University, Aeronautics University's project. We have 30000+ buyers in domestic market, succeed in establishing the branch companies and maintenance department in Dongguan, Shanghai, Beijing, Jinjiang, Wuhan, Chongqing, Shenyang, Changsha. Our products owned CE/ISO/ASTM/ ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on.

ZME Instrument owned CE/ISO/ASTM/ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on. Lixian Instrument have a professional R & D team and a reliable quality management system, which introduced the CNC processing center and CNC lathe and other advanced equipment in 2010, successfully obtained the CMC measurement certificate and passed ISO 9001 system authentication.

Package & transport

FAQ

Q1: What is your warranty?

A: 12 months product warranty, but lifetime for services. Free Non-consumable components will be provided if any performance failure occurs within 12 months caused by non-human damage.

Q2: How-to vedio provided?

A: Yes. if required, our engineers will record a specialize how-to video for you.

Q3: Are your company a trading one or a factory?

A: Yes, we are a manufactured factory & trade company (integration). 23 years focusing on test instruments field. 13 years exporting experience, warmly welcome to visit our plant (factory), we also support OEM and ODM.

Q4: After an order is placed, when to deliver?

A: If we have inventory, we can arrange shipment within 7 days. Please be aware that our production lead times depend on specific items and item quantities.

Q5: What about the after-sales service and product’s quality?

A: 12 months warranty. After the warranty, the professional after-sale service team will provide perfect technical support.and help customer solve problems encountered while using our product, handies guest problems and complaints professionally and timely. Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. Engineers would be go abroad to training, repair and others help you need.

Q6: what about the packing of equipment?

A: Covered with air bubble film before put the machine into the stanard exporting wooden case, which not only has good shock absorption, impact resistance, heat sso has the advantag- es of nontoxic, odorless, moisture corrosion, good transparency etc.

.png)