Model HZ-9701A Belt Drive Balancing Machine

|

Model

|

HZ-9701A-1

|

HZ-9701A-1.6

|

HZ-9701A-5S

|

HZ-9701A-10X

|

HZ-9701A-16

|

HZ-9701A-20

|

|

Max Mass of Workpiece(kg)

|

1

|

1.6

|

5

|

10

|

16

|

20

|

|

Max Diameter of Workpiece

|

Ø260mm

|

Ø360mm

|

Ø360mm

|

|

Distance Between Two Support Bearings (mm)

|

20-550

|

40-550

|

|

V-Shape Journal Diameter Scope of Workpiece (mm)

|

Ø3-Ø20

|

Ø3-Ø30

|

Ø5-Ø40

(With roller bracket)

|

Ø10-Ø40

(With roller bracket)

|

Ø10-Ø40

|

|

Diameter Scope of Driving Belt (mm)

|

Ø10-Ø120

|

Ø10-Ø150

|

Ø10-Ø200

|

|

Balance speed (r/min) (when dragging workpiece diameter Ø100)

|

400-3000,frequency conversion stepless speed regulation

|

|

Motor Power (kw)

|

0.25

|

|

Minimun achieveable residual unbalance(gmm/kg)

|

emar≤0.3

|

emar≤0.5

|

|

Unbalance reduction rate (%)

|

URR≥95%

|

|

Measuring system

|

Lixian special software

|

|

Note: The technical parameters of the above series of balancing machines are for reference only. The specific parameters and quotations need to be determined according to the actual situation of the rotor of the user's workpiece, and can also be customized.

|

Unbalance amount calculation

Where mper is the allowable unbalance:

M: represents the weight of the rotor, the unit is kg

G: represents the balance accuracy grade of the rotor, the unit is mm/s

r : represents the correction radius of the rotor, the unit is mm

n: represents the speed of the rotor, the unit is rpm.

The balanced quality grades of commonly used various rigid vermilion drills dynamic balance test machine

|

G 40

|

40

|

Automobile wheels, hubs, rims, wheel assemblies, drive shafts, elastically installed six-cylinder or more high-speed four-stroke (gasoline or diesel) engine crankshaft drive devices, and engine crankshaft drive devices for automobiles, trucks and locomotives.

|

|

G 100

|

100

|

Crankshaft drive device of six-cylinder or more high-speed diesel engine, complete engine (gasoline or diesel) of automobile, truck and locomotive

|

|

G 250

|

250

|

Rigidly mounted high-speed four-cylinder diesel engine crankshaft drive device

|

|

G 630

|

630

|

Rigidly installed crankshaft drive device of large four-stroke engine, elastically installed crankshaft drive device of marine diesel engine

|

|

G 1600

|

1600

|

Rigidly mounted crankshaft drive device of large two-stroke engine

|

|

G 4000

|

4000

|

Crankshaft drive device of low-speed marine diesel engine with odd number of cylinders rigidly installed

|

|

Note: Before you choose a balancing machine, you should first determine the balance level of the rotor

|

HZ-9701A Power Requirements and Cords

Power requirements

Table 2. HZ-9701A Power requirements

|

Parameter

|

Specification

|

|

Maximum Power (VA)

|

256

|

|

Single Phase Voltage (Vac) (±10%)

|

220~240,100~120 (customize)

|

|

Frequency - Hz

|

47 to 63

|

|

Length of Power Cable - m (ft)

|

2.44 (8)

|

Company Profile

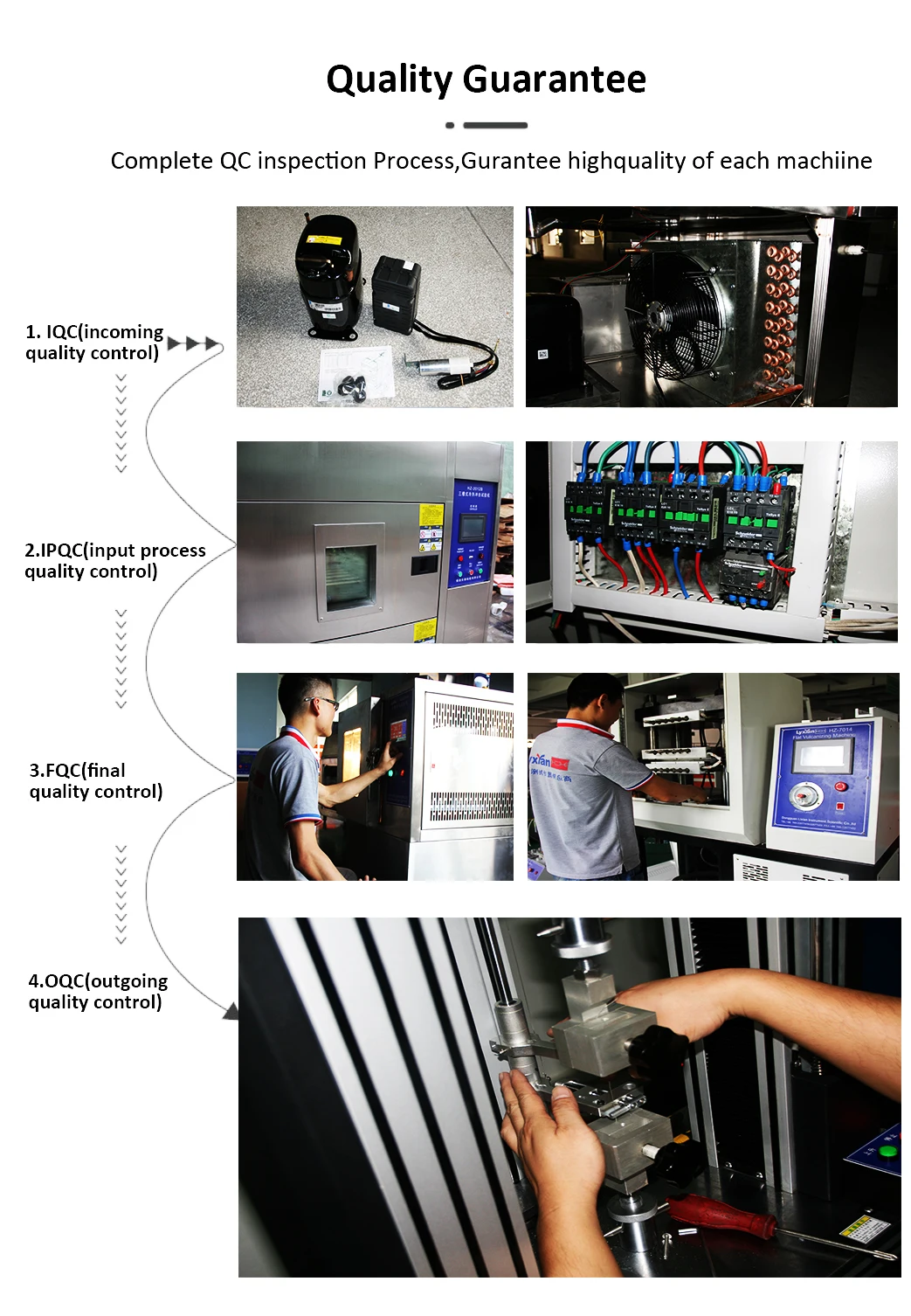

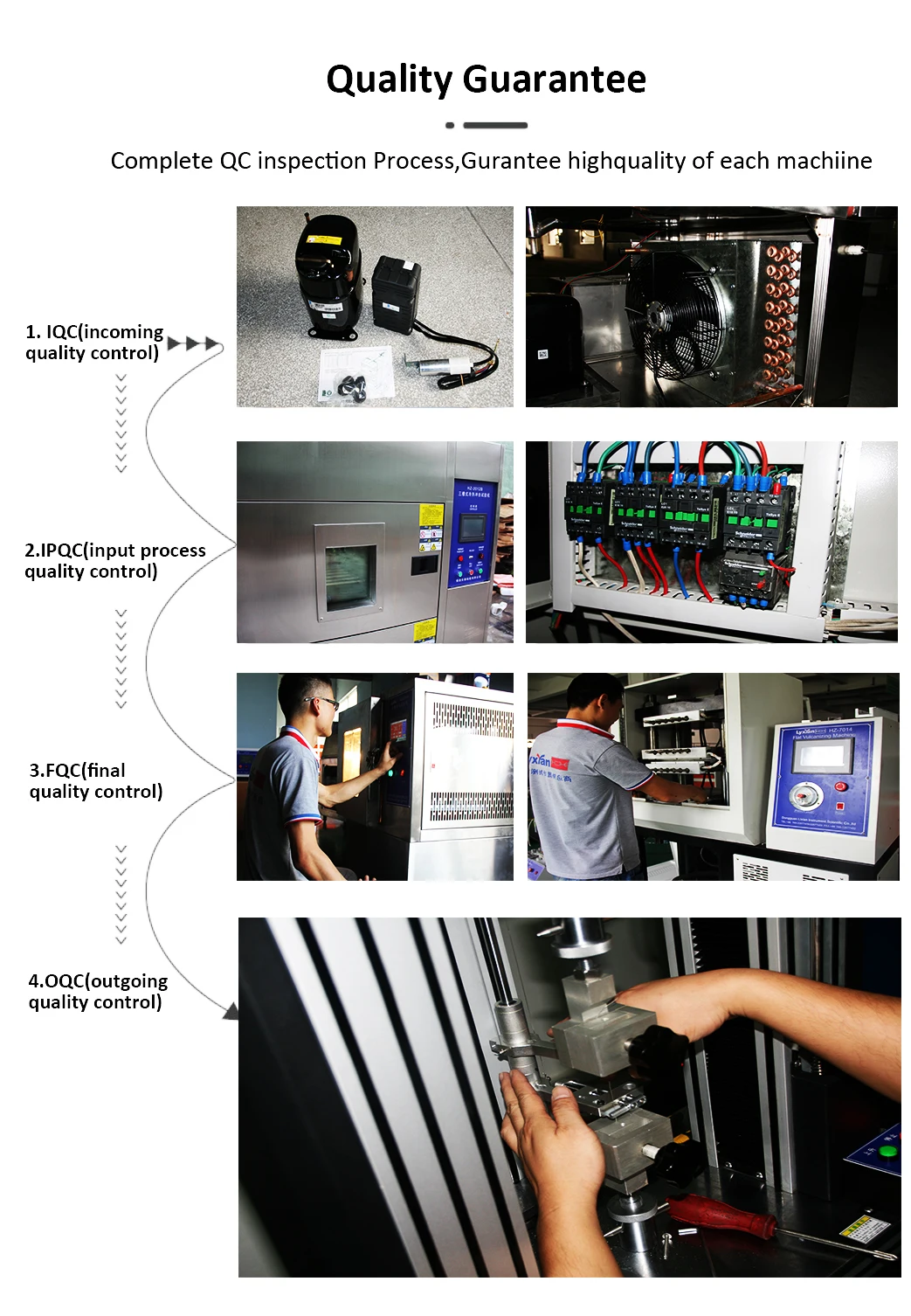

Dongguan ZME Machine Trading Co.,td is one of the leading manufacturers of advanced testing instruments, founded on 2000, located in Dongguan, Guangdong province in China. Dongguan ZME Machine Trading Co.,td located in Dongguan city, covers an area of 6000 square meters, take the lead in introducing the CNC processing center and NC lathe and other advanced equipment in 2010. Carried on several listed company lab, quality institutions, Tsinghua University, Aeronautics University's project. We have 30000+ buyers in domestic market, succeed in establishing the branch companies and maintenance department in Dongguan, Shanghai, Beijing, Jinjiang, Wuhan, Chongqing, Shenyang, Changsha. Our products owned CE/ISO/ASTM/ ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on.

ZME Instrument owned CE/ISO/ASTM/ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on. Lixian Instrument have a professional R & D team and a reliable quality management system, which introduced the CNC processing center and CNC lathe and other advanced equipment in 2010, successfully obtained the CMC measurement certificate and passed ISO 9001 system authentication.