- Product Details

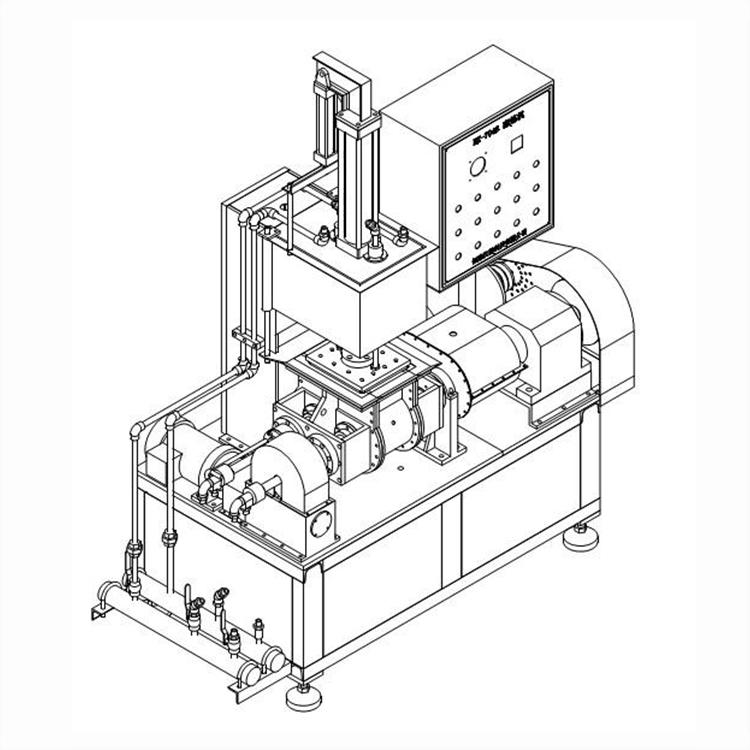

Banbury Kneader with Taiwan technical drawings, advanced technology in China and imported core components, this machine has character itself as environmental-friendly, high-efficiency and good dispersing effect, with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production.

Equipment summary:

Banbury Kneader with Taiwan technical drawings, advanced technology in China and imported core components, this machine has character itself as environmental-friendly, high-efficiency and good dispersing effect, with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production. It can also be used in electric wire, cable, electronics, sole, sports equipments and auto parts industries for rubber, plastic and chemical production mixing and plasticizing.

Detailed Product Description:

Banbury Kneader is applicable to rubber, plastic and chemical industry. And most suitale kneading application: EVA., rubber, TPR, sole, rubber roller, hoses, belts, sponges, vibration insulator, elastic cord, sealing materials, tire, tapes, master batches, pigment, ink, electric rubber parts, chemical industry compounds.

The feature for dispersion kneader:

1. An automatic temperature and time control system to provide a 100% mixing result.

2. Easy to clean chamber and changing colors.

3. In6~10minutes/batch of output equivalent to 2 units of open mixing mill.

4. Pressurized and sealed mixing chamber to provide high mixing performance and prevent the environment.

5. Easy installation, operation and maintenance, lower the running cost.

Technical parameters:

Banbury Kneader with Taiwan technical drawings, advanced technology in China and imported core components, this machine has character itself as environmental-friendly, high-efficiency and good dispersing effect, with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production. It can also be used in electric wire, cable, electronics, sole, sports equipments and auto parts industries for rubber, plastic and chemical production mixing and plasticizing.

Detailed Product Description:

Banbury Kneader is applicable to rubber, plastic and chemical industry. And most suitale kneading application: EVA., rubber, TPR, sole, rubber roller, hoses, belts, sponges, vibration insulator, elastic cord, sealing materials, tire, tapes, master batches, pigment, ink, electric rubber parts, chemical industry compounds.

The feature for dispersion kneader:

1. An automatic temperature and time control system to provide a 100% mixing result.

2. Easy to clean chamber and changing colors.

3. In6~10minutes/batch of output equivalent to 2 units of open mixing mill.

4. Pressurized and sealed mixing chamber to provide high mixing performance and prevent the environment.

5. Easy installation, operation and maintenance, lower the running cost.

Technical parameters:

| Model | HZ-7048 Banbury Kneader |

| Volume | 1L, 2L, 3L, 4L, 5L |

| Productivity | 0.6-3kg/time |

| Drive motor | 2.2KW |

| Turning motor | 0.4KW |

| Turning angle | 110° |

| Rotor speed | 0-80r/min |

| Air Compressor | 2.2KW |

| The maximum pressure of the mound | 0.3MPa |

| Discharge method | quick opening |

| Feeding Method | Front materials |

| Water cooling (rubber mixing) | 0.2-0.4MPa |

| Electric heating | 1KW |

| Weight | 600KG |

| Dimension | 1600X700X2000mm |

| Power | 380V AC |

Customized capacity:

| Capacity (L) | 1 | 2 | 3 | 5 | 10 | 15 | 20 | 25 | 35 | 55 | 75 |

| Drive motor (kW) | 2.2 | 5.5 | 5.5 | 7.5 | 15 | 22 | 30 | 37 | 55 | 75 | 110 |

| Rotating motor (kW) | 0.2 | 0.2 | 0.4 | 0.4 | 0.75 | 1 | 1.5 | 1.5 | 2.2 | 3 | 4 |

| Turning angle | 110° | 110° | 110° | 110° | 110° | 110° | 110° | 110° | 140° | 140° | 140° |

| Air Compressor (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 |

| Cooling water (MPa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

| Electric heating (kW) | 0.7 | 0.8 | 1.2 | 1.8 | 1.9 | 2.1 | 4 | 4.5 | 10 | 15 | 18 |

| Weight (kg) | 800 | 900 | 1000 | 1200 | 2300 | 2800 | 4500 | 5000 | 6500 | 7800 | 10800 |