- Product Details

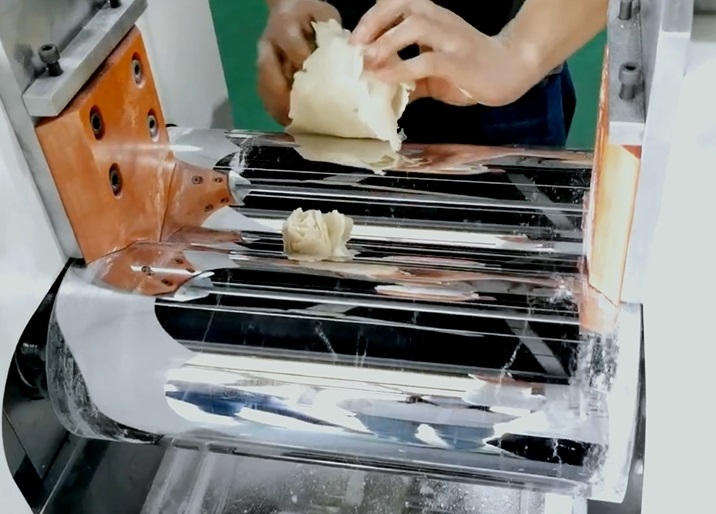

Rubber Mixing Mill suitable for plastic industry polymer material mixing and processing such as, PVC, color master batch. Making the raw material and compound mixing, and achieve the required color and quality. The machine adopts special heated mold, roll surface temperature uniformity, never take off a layer, sample thickness can be mixed, the machine safety protection device, convenience to use.

Reference standard:

GB 6038-2006 Rubber ingredients of rubber testing, mixing and Vulcanization equipment and operating procedures.

GBT 13577-1992 Mill for rubber and plastics

HGT 2149-2004 Open rubber mixing machine, plastic mixing mill test methods

JBT 53113-1999 Open plastic mixing mill product quality grading

Technique Feature:

⑴ The core technology from Taiwan, The main parts adopt the French schneider.

⑵ The whole floor, easy installation, driving mode is uniaxial output ensure the torsion big, Imported bearings reduce rubbing force to ensure save electricity, low noise and rubber thickness uniform parallel controllable.

⑶ Roll adopts the vanadium titanium alloy chilled cast iron,roll hardness (HRC) 50-60, surface is hard wear-resisting, durable. Roller lumen finish machining to ensure that the roller body cooling quickly and evenly.

⑷ The machine adopts manual adjustment mode, Thickness control precision, easy operation, High safety factor .

⑸ The machine is equipped with an emergency brake, When emergency accidents,four corners have emergency switch, a number of brake system, convenient quick stop machine.

⑹ Transmission device adopts hardened reducer, compact structure, transmission efficiency, little noise.

⑺ Automatic oiling device to ensure that long-term oil for driving part,Make up the pump forget supply damage to part of serious consequences.

(8) Two motor driven, arbitrary roller speed ratio before and after implementation, easy to operation.

(9) Integral plate, easy installation.Driving mode is uniaxial output to ensure the big torque,imported bearings to reduce friction to save electricity, reduce noise, and Rubber thickness uniform parallel controllable.

(10) Transmission device adopts double double frequency converter control, Low noise, long service life.

Technical parameters:

GB 6038-2006 Rubber ingredients of rubber testing, mixing and Vulcanization equipment and operating procedures.

GBT 13577-1992 Mill for rubber and plastics

HGT 2149-2004 Open rubber mixing machine, plastic mixing mill test methods

JBT 53113-1999 Open plastic mixing mill product quality grading

Technique Feature:

⑴ The core technology from Taiwan, The main parts adopt the French schneider.

⑵ The whole floor, easy installation, driving mode is uniaxial output ensure the torsion big, Imported bearings reduce rubbing force to ensure save electricity, low noise and rubber thickness uniform parallel controllable.

⑶ Roll adopts the vanadium titanium alloy chilled cast iron,roll hardness (HRC) 50-60, surface is hard wear-resisting, durable. Roller lumen finish machining to ensure that the roller body cooling quickly and evenly.

⑷ The machine adopts manual adjustment mode, Thickness control precision, easy operation, High safety factor .

⑸ The machine is equipped with an emergency brake, When emergency accidents,four corners have emergency switch, a number of brake system, convenient quick stop machine.

⑹ Transmission device adopts hardened reducer, compact structure, transmission efficiency, little noise.

⑺ Automatic oiling device to ensure that long-term oil for driving part,Make up the pump forget supply damage to part of serious consequences.

(8) Two motor driven, arbitrary roller speed ratio before and after implementation, easy to operation.

(9) Integral plate, easy installation.Driving mode is uniaxial output to ensure the big torque,imported bearings to reduce friction to save electricity, reduce noise, and Rubber thickness uniform parallel controllable.

(10) Transmission device adopts double double frequency converter control, Low noise, long service life.

Technical parameters:

| Model | HZ-7015 Rubber Mixing Mill |

| Roller Diameter | 120mm/4in; 160mm/6in; 200mm/8in; 250mm/10in |

| Roller face width | 320mm |

| Mixing capacity | 0.3~2kg, 0.5~3kg, 1~10kg, 2~15kg |

| Picking device | SUS304 Stainless steel hopper |

| Roller temperature | RT~300°C |

| Heating method | electrical heating OR water-cooled cooling |

| Temp Accuracy | ±3°C |

| Temperature controller | PID control |

| Roller Rev | frequency control |

| Roller ratio | 1:1.22/1:1.35; 1:1.22/1:1.35; 1:1.1/1:1.22; 1:1.1/1:1.22 |

| Roller hardness | 50~60HRC |

| Roller processing | Mirror polishing chrome plated |

| Roller spacing | 0.1~8mm, 0.1~10mm (adjustable) |

| Spacing display mode | Calibration/digital display |

| Safety device | Collision type emergency stop |

| Safety device number | 7 PCS |

| Special function | Emergency stop inversion |

| Motor power | 4.5KW, 5.5KW, 7.5KW, 15KW |

| Power voltage | 3 phase,AC380V |

| Dimension (m) | 1*1.1*1.4; 1*1.1*1.5; 1.5*1.2*1.5; 1.5*1.3*1.6 |

| Weight | 2T; 2.5T; 3.4T; 4T |