- Product Details

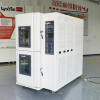

Thermal Shock Chamber Description:

temperature shock test chamber is for electrical and electronic components, automation components, communication components, auto parts, metals, chemical materials and plastics industries, defense, aerospace, military industry, BGA, PCB base plate, electronic chip, IC, semiconductor ceramic and high-Changes in the physical sacrifice of molecular materials, test the material on the high and low tension and products arrived repeated thermal expansion and contraction of output in the chemical changes or physical injury, to confirm the quality of products, from the precision of the IC component to heavy machinery, and both need it the ideal test tool.

Main features:

1. Large color LCD touch interactive microcomputer control system, easy to understand, running at a glance;

2. Closed imported compressor + environmental refrigerant, cold plate heat exchanger and dual-type ultra-low temperature refrigeration systems;

3. A LAN network communication interfaces to computer remote control, easy to use;

4. Independently set the heat, cold and hot and cold conditions, the impact of three different function, the impact of the implementation of hot and cold conditions, with high and low temperature testing machine functions;

5. Operation at boot time automatically make an appointment ahead of pre-cooling, preheating, standby;

6. Defrost cycles can be set and the number of automatic (manual) defrost;

7. Controller friendly interface and easy procedure setting, abnormal and troubleshooting display complete.

Technical parameters:

| Model | 2012A-49 | 2012A-80 | 2012A-150 | |

| Size (W×H×D)mm | Inner box | 35×35×40 | 50×40×40 | 60×50×50 |

| Outer box | 150×195×145 | 180×200×145 | 190×200×155 | |

| High-temperature range | 80°C~200°C | |||

| Low-temperature range | -55°C~-10°C | -65°C~-10°C | -75°C~-10°C | |

| Testing room temperature | High | 60°C~150°C | ||

| Low | -10°C~-40°C | -10°C~-55°C | 10°C~-60°C | |

| Heating-up time | 60°C~200°C about 25min | |||

| Cooling time | 20°C~-55°C about 60min | 20°C~-65°C about 75min | 20°C~-75°C about 90min | |

| Impact recover time | High-temperature (150°C) about 30min Low-temperature (-40°C or -55°C or -60°C) about 30min Impact recover time 5min | |||

| Inner material | SUS#304 stainless steel | |||

| Outer material | US#304 stainless steel | |||

| Insulation | High-precision glass wool + PU foam rubber | |||

| Cooling system | Copy blowing type or water-cooled, and environmental protection refrigerant. | |||

| Controller | Man-machine interface with touch-programmable control | |||

| Protector | Compressor slide off, overheating, over-temperature, over-pressure, dry heat, motor overload protection switch | |||

| Attachment | Compartment frame 2, the test hole 1 | |||

| Power | 16KW | 32KW | 48KW | |

| Power supply | AC380V±10%, 3PH 50/60Hz | |||