The properties of the fibers in a yarn play a major role in the functionality and aesthetics of the yarn. Modifications to these fibers can affect the properties of the yarn

in a variety of ways. During the development and post-development of the yarn, tensile testing is performed according to ASTM D3822 to evaluate the mechanical

properties of the fibers or filaments. Tensile testing is also performed during the manufacturing process as a quality control measure to confirm that the material meets

specifications.

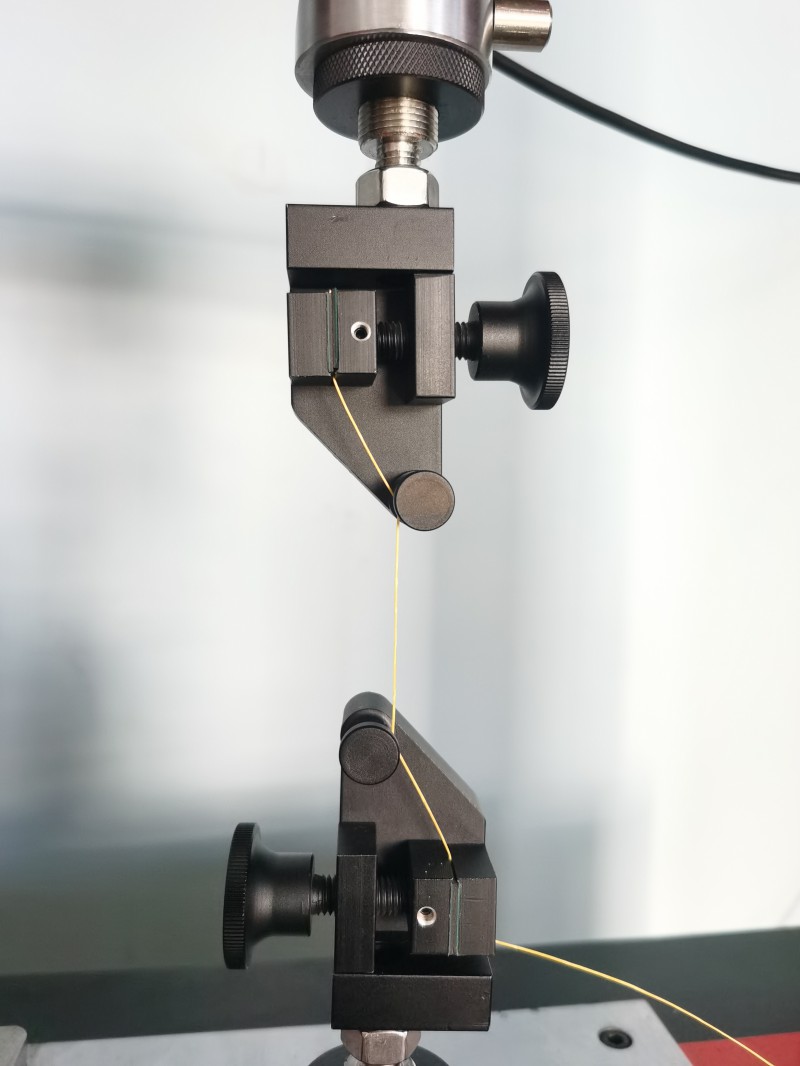

When dealing with very delicate textiles, it is often difficult to determine the most appropriate test configuration. It is important to select a grip that allows for easy

mounting and removal of the sample. In some cases, making tabs with tape may make mounting the sample easier. This is especially true when the sample is so small

that it is difficult to see with the naked eye. If the right grip is used, sample slippage or sample failure within the grip will not occur.

Individual fibers can be very fragile and can fail at very low loads. It is important to select the right load cell to achieve maximum accuracy at low forces. In this case,

Lixian's 5N load cell is the best choice.

There are a variety of grips that are suitable for single strands of fiber. If the specimen is long enough, we recommend using rope and yarn style grips, which can

reduce the likelihood of premature specimen failure and help maintain alignment. 50 N pneumatic side action grips may also be suitable for this application and

can be used in many cases.