- Product Details

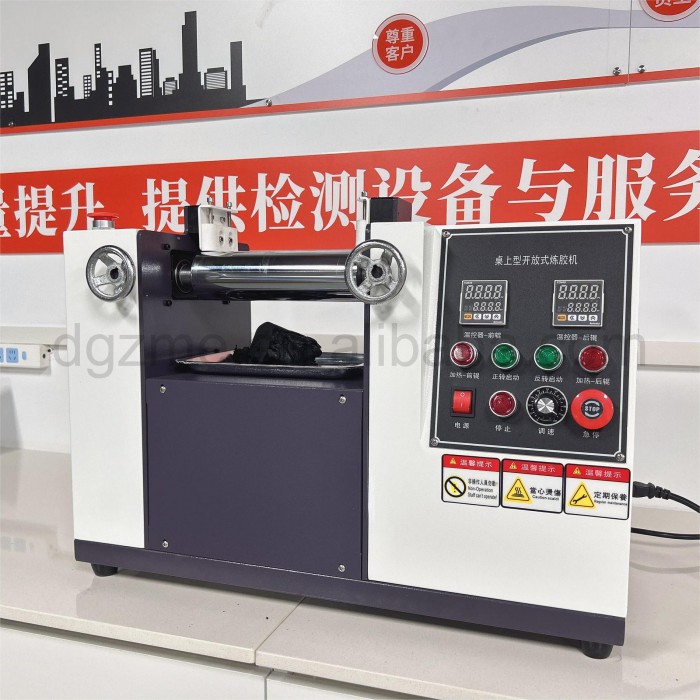

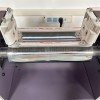

Equipment Overview:

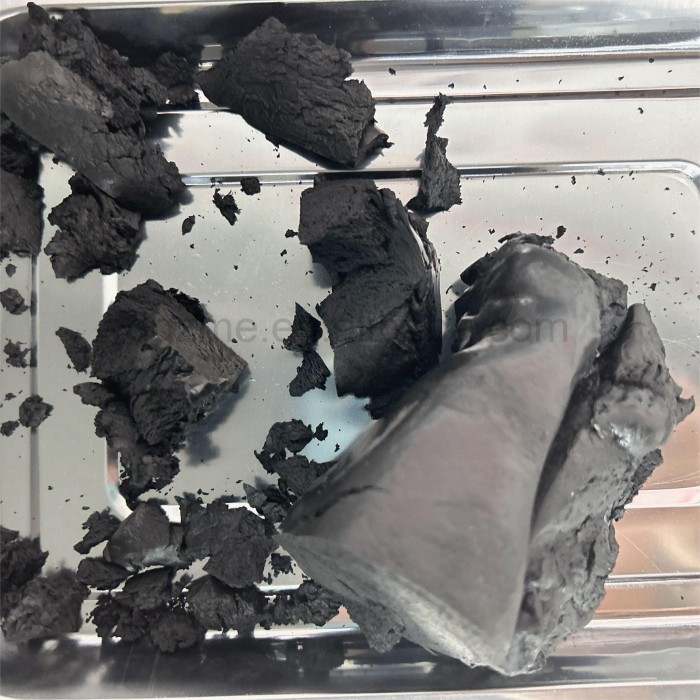

The purpose of the double roll open mill is to mix and beat plates for color comparison or testing, mainly used in the rubber industry, color powder industry, silicone industry, etc. By heating or not heating, the raw materials are repeatedly squeezed and mixed through the double roll drum to produce single color samples for various purposes. This machine is equipped with forward rotation, reverse rotation, emergency stop function devices, spacing adjustment function, and double roll temperature control devices.

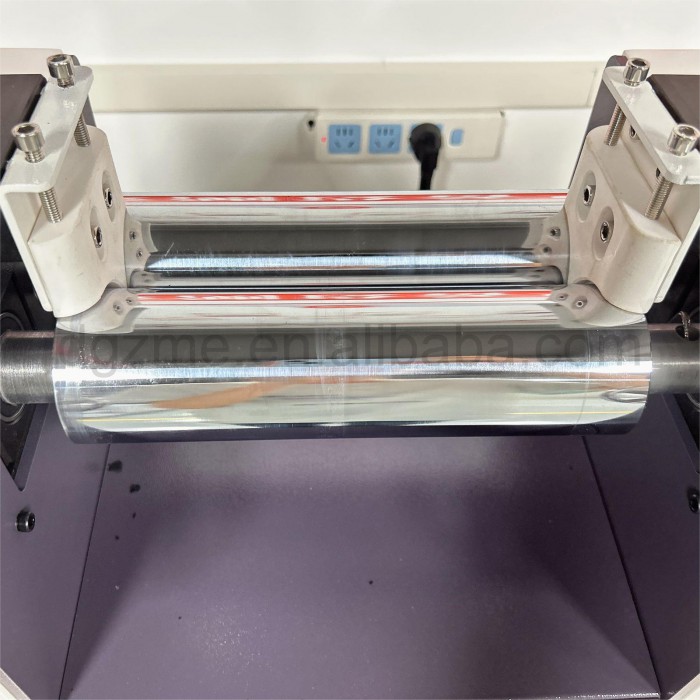

Desktop open rubber mixing machine is a type of rubber mixing machinery with exposed rollers used in rubber factories to prepare plastic rubber, mix rubber, or perform hot refining and molding. The main working components are two hollow rollers or drilling rollers that rotate inward in opposite directions. The one installed on the operator's side is called the front roller, which can be manually or electrically moved horizontally to adjust the roller distance and meet operational requirements; The rear roller is fixed and cannot move forward or backward. The two rollers are generally of the same size and rotate relative to each other at different speeds. Raw rubber or rubber material is drawn into the gap between the two rollers as the rollers rotate, and is subjected to strong shear force to achieve the purpose of plasticizing or mixing. Refining machines are also used in departments such as plastic processing.

Technical Parameter

model | HZ-Z7015 |

Roll diameter (metric/imperial) | 65mm/2.5in |

Roll surface width | 230mm |

Mixed Capacity [Soft Adhesive] | 0.1~0.5kg |

Material receiving device | SUS304 |

Roller temperature [choose one based on quotation] | Room temperature/Room temperature -250 ℃ |

Temperature uniformity | 5 ℃ |

Temperature controller | Imported from South Korea |

Bei tube speed ratio [constant speed] | 01:01.3 |

Roller hardness | 0-60HRC |

Roller processing | Mirror polished chrome plating |

Roller spacing | 0.1-4mm adjustable |

speed | 10-40r/min |

Spacing display method | scale |

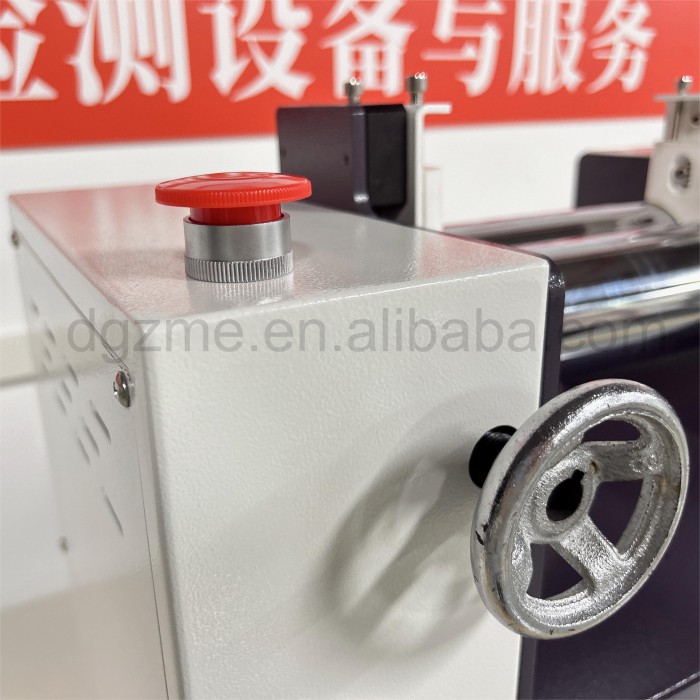

Safety devices | Collision type emergency stop |

Number of safety devices | Two |

Special functions | Emergency stop |

Motor power | 2.2KW * 1 |

supply voltage | AC220V |

Machine size | 650 X350 X580mm |

Overall weight | 275.0k |