- Product Details

The single sample vulcanized rubber low temperature brittleness tester is used to measure the highest temperature of the vulcanized rubber sample when it is damaged by impact under specified conditions, that is, the brittle temperature. It can be used to make comparative identification of the performance of non-rigid plastics and other elastic materials under low temperature conditions. It can measure the brittle temperature and low temperature performance of different rubber materials or vulcanized rubber with different formulas. Therefore, it is indispensable in scientific research materials and product quality inspection, production process control and other aspects.

Standards met:

The rubber and plastic low temperature brittleness tester is designed according to the national standard GB-T1682-1994 for the determination of low temperature brittleness of vulcanized

rubber, and all technical indicators meet the requirements of the national standard.

Purpose of the equipment:

The rubber and plastic low temperature brittleness tester can determine the brittle temperature and low temperature performance of different rubber materials or vulcanized rubber with

different formulas. Therefore, it is indispensable in scientific research materials and quality inspection of their products, production process control, etc.

Industry of application:

Rubber industry

Features of the equipment:

This equipment pushes the clamp through the main cylinder to make the sample extend into the freezing medium, and lifts the clamp after a certain period of time, and then the auxiliary

cylinder controls the impact process, observes the degree of damage to the sample, and through repeated tests, determines the lowest temperature when at least two samples are not

damaged and the highest temperature when at least one sample is damaged. If the difference between these two results is no more than 1°C, the test is over.

Structural composition:

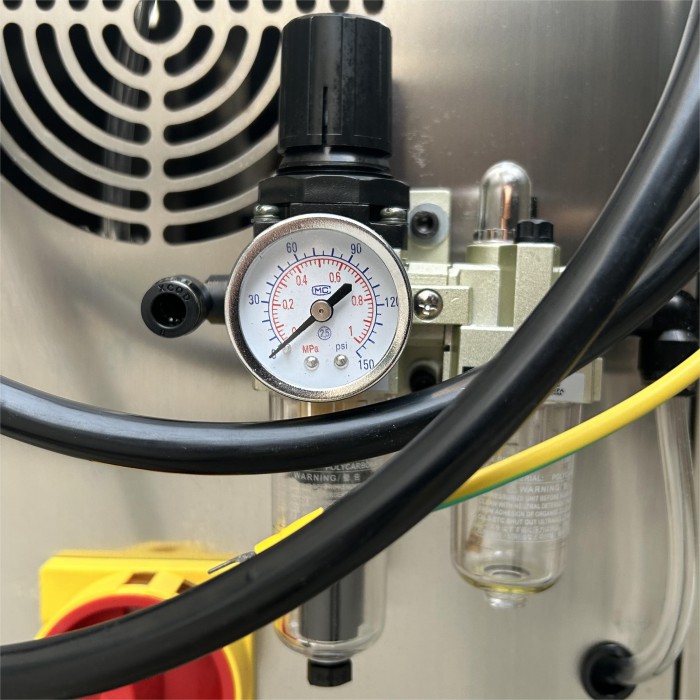

This equipment consists of a workbench, a lifting clamp, an impact device, a low temperature thermometer, a cold well containing freezing medium, a compressor, etc.

Technical parameters:

Model | HZ-7004 |

Test temperature | -60℃--0℃ |

Impact speed | 2m/s ±0.2m/s |

After constant temperature, temperature fluctuation within 3min of test | <±0.5℃ |

Distance from the center of the impactor to the lower end of the clamp | 11±0.5mm |

Dimensions (length*width*height) | 1100*800*800mm Height of exposed cylinder accessories: 500 |

Inner box dimensions (length*width*height) | 300*250*400mm |

Refrigeration medium | Alcohol |

Power | 1100W |

Can meet the test piece size | (length) 25~40mm (width) 6±1mm (thickness) 2.0±0.2mm |