- Product Details

Product Description

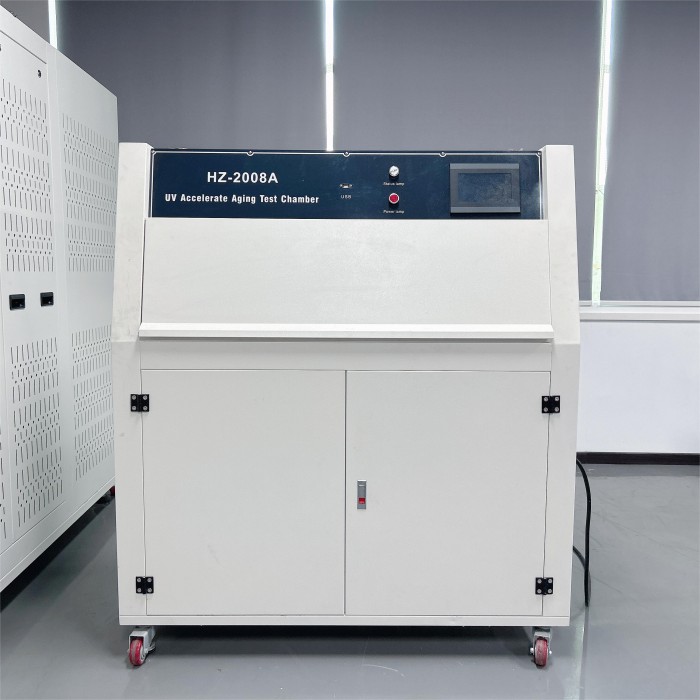

Equipment summary:

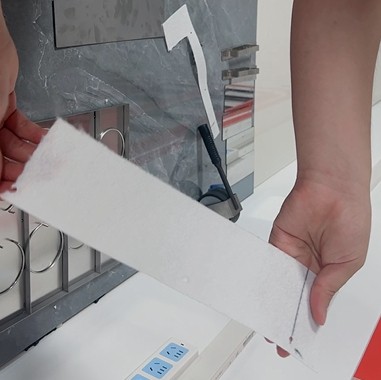

Textile UV aging testing machine can simulate the sun, rain and dew to damage the material, using UV lamp simulate the effect of sunlight, cold rain and dew. Being tested textile materials are placed in a certain environment which the light and moisture are alternating. The textile materials are tested for several days or weeks, you can know the damage of material at outside for several months or several years, Damage types include: bleaching, discoloration, loss of light, powder, crack, turbidity, bubble-based, embrittlement, strength decline and oxidation.

Textile UV aging testing machine can simulate the sun, rain and dew to damage the material, using UV lamp simulate the effect of sunlight, cold rain and dew. Being tested textile materials are placed in a certain environment which the light and moisture are alternating. The textile materials are tested for several days or weeks, you can know the damage of material at outside for several months or several years, Damage types include: bleaching, discoloration, loss of light, powder, crack, turbidity, bubble-based, embrittlement, strength decline and oxidation.

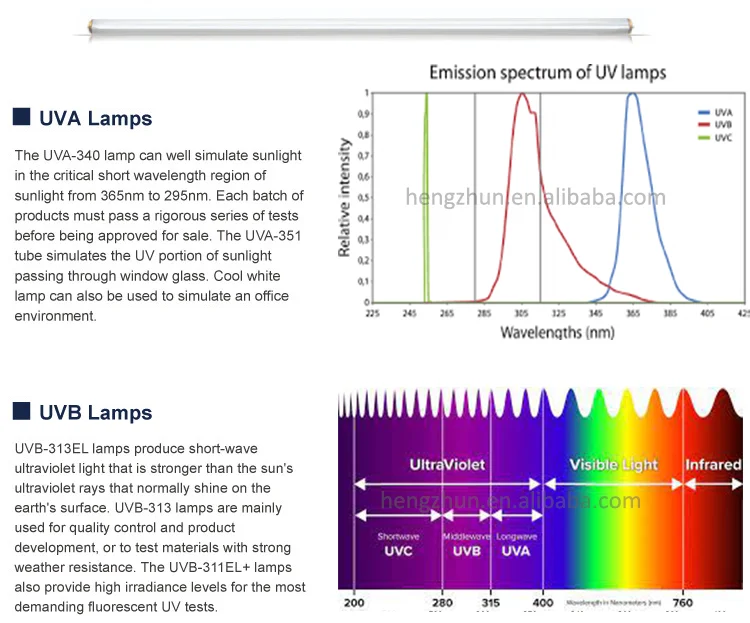

Main Functions

Fabric UV test machine, the UV lamp can simulate the effect of the sun, condensation and water spray system can simulate the effect of rain and dew. the temperature can be controlled at the process of testing. A typical test cycle is usually testing at UV radiation of high temperature and the 100% humidity at dark; Typically used in paint and coatings, automotive, plastic products, wood products, glue, etc. ISO4892-2

Specification

The Water Spray System for Some Applications.

the water spray can better simulate the end use of the environmental conditions.Water spray in a simulated drastic changes in temperature and rainfall caused by the thermal shock or mechanical erosion is very effective.Conditions in some practical applications, such as sunlight, heat together the stroke of showers dissipated rapidly, the material will be dramatic changes in temperature, thermal shock, thermal shock for many materials, this is a part of test.QUV water spray to simulate thermal shock and stress corrosion.Sprinkler system with 12 nozzles, each side in the test room of 6; sprinkler system can run a few minutes and then shut down.This short cooling water samples quickly and create a thermal shock conditions.

the water spray can better simulate the end use of the environmental conditions.Water spray in a simulated drastic changes in temperature and rainfall caused by the thermal shock or mechanical erosion is very effective.Conditions in some practical applications, such as sunlight, heat together the stroke of showers dissipated rapidly, the material will be dramatic changes in temperature, thermal shock, thermal shock for many materials, this is a part of test.QUV water spray to simulate thermal shock and stress corrosion.Sprinkler system with 12 nozzles, each side in the test room of 6; sprinkler system can run a few minutes and then shut down.This short cooling water samples quickly and create a thermal shock conditions.

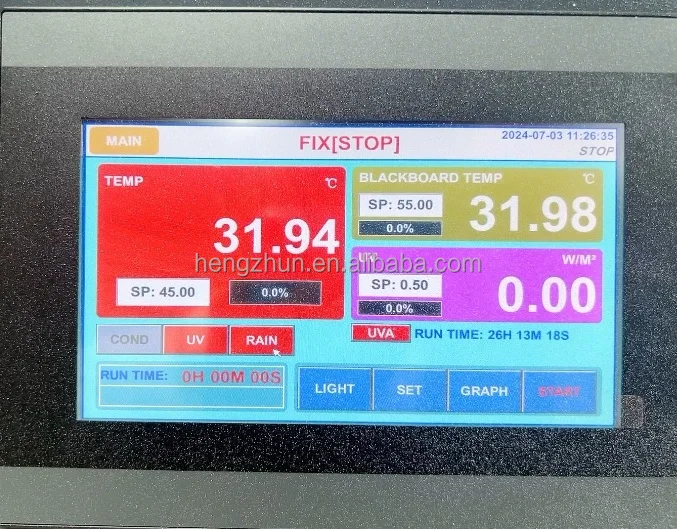

The Temperature Control in Each Cycle

The temperature can be controlled at a set value.At the same time the board can monitor the temperature of the thermometer.Higher temperature can accelerate the aging process, while temperature control for reproducibility of the test is also very important.

Recommend Products

Salt Spray Chamber Walk in Test Chamber Climate test Chamber UV Test Chamber

Xenon Test Chamber Thermal shock Test Chamber Rain Test Chamber High Temp. Test Chamber