Engineered for Accuracy, Built for Compliance: Meet the Next Generation of Adhesion Testing Technology

Introduction:

In industries where bond strength determines product integrity—from automotive composites to medical device adhesives—a single micron of inconsistency can lead to catastrophic failures.

How confident are you in your material's adhesive properties?

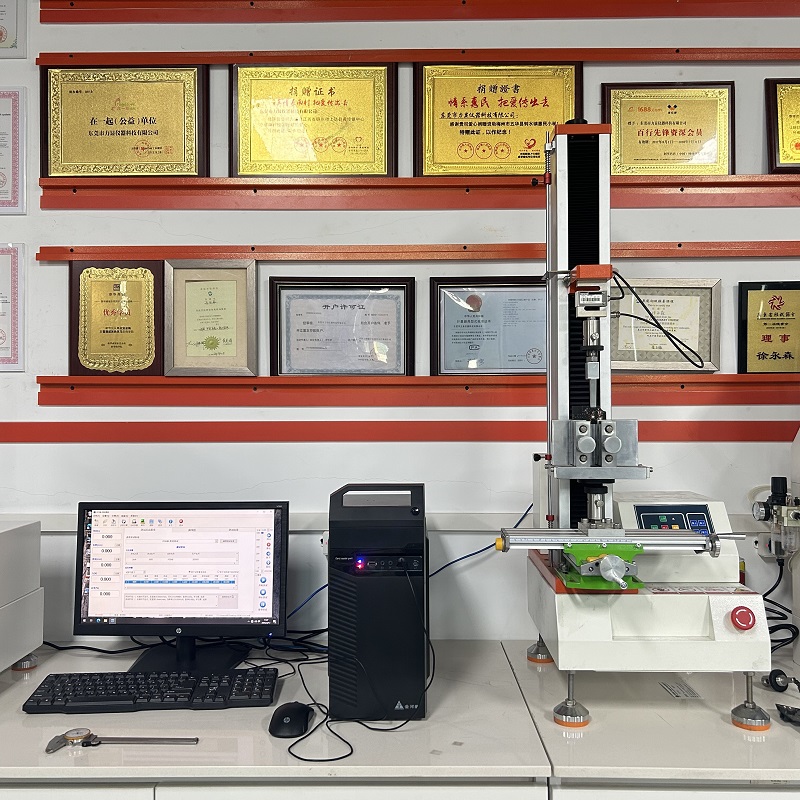

At Dongguan Lixian Instrument Science Co., Ltd., we redefine precision with our Advanced Peel Testing Machines, delivering laboratory-grade accuracy that meets ASTM D903, ISO 8510,

and FDA 21 CFR Part 11 compliance. Trusted by Fortune 500 manufacturers and cutting-edge R&D labs, our peel testers are the gold standard in quantifying adhesion strength.

Why Our Peel Tester Stands Out?

✅ Micro-Newton Precision: Patented load cells (0.1% accuracy) detect peel forces as low as 0.001 N/mm, ensuring even ultra-thin films and nano-coatings are tested flawlessly.

✅ Smart Automation: Pre-programmed test protocols for 90° Peel, 180° Peel, and T-Peel Tests with real-time graph generation and CSV exports.

✅ Material Versatility: Test everything from pressure-sensitive adhesives (PSAs) to aerospace-grade epoxy bonds with interchangeable grips.

✅ Durability Redefined: 316L stainless steel construction withstands 10,000+ test cycles—ideal for high-throughput QA labs.

Industry Applications: • EV Battery Manufacturing: Validate bonding integrity of lithium-ion cell stack laminations.

• Medical Device Production: Ensure surgical tape peel strength meets ISO 11608 standards

. • Packaging Innovation: Optimize seal strength for biodegradable films and retort pouches.

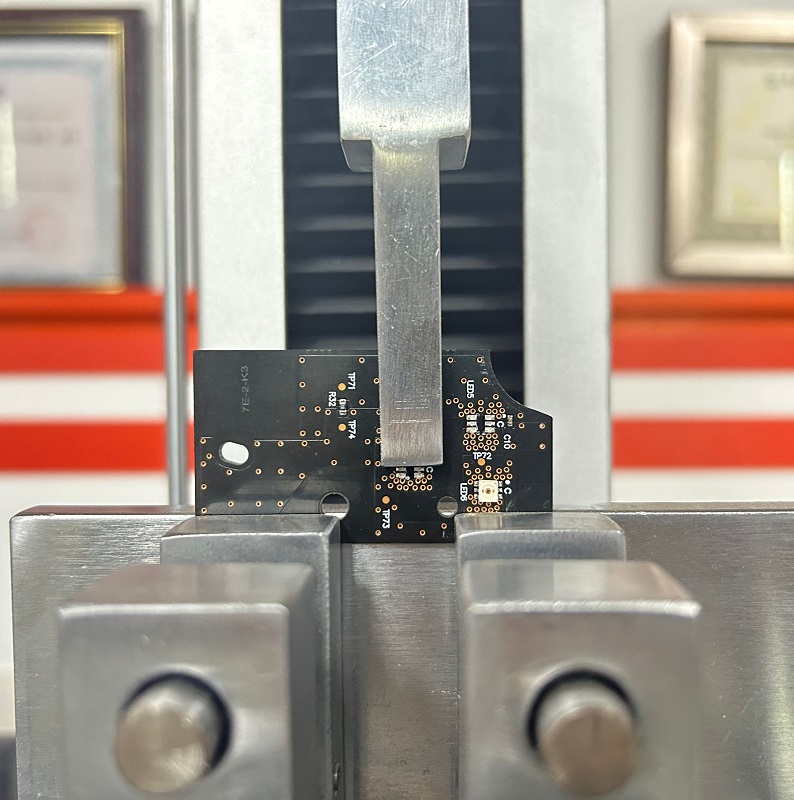

• Electronics Assembly: Test FPC (flexible printed circuit) adhesion under thermal cycling.

Case Study Snapshot:

A leading EV manufacturer reduced warranty claims by 18% after implementing our AutoPeel Pro Tester to detect under-cured battery adhesive layers.

“The automated JIS Z0237 compliance reports cut our certification time by 40%.” – QA Director, Top 3 Automotive Supplier

Technical Highlights

• Peel Force Range: 0.001 N to 5 kN

• Test Speed: 0.1–500 mm/min (digital servo control)

• Compliance: ASTM D903, ISO 8510, EN 1464, GB/T 2792

• Software: 21 CFR Part 11-compliant PeelAnalyzer Pro with AI-driven anomaly detection