- Product Details

Equipment summary:

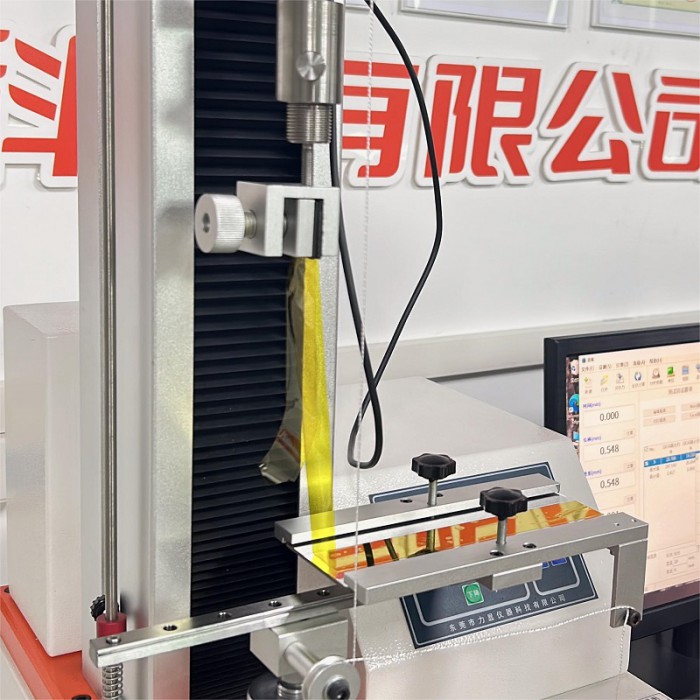

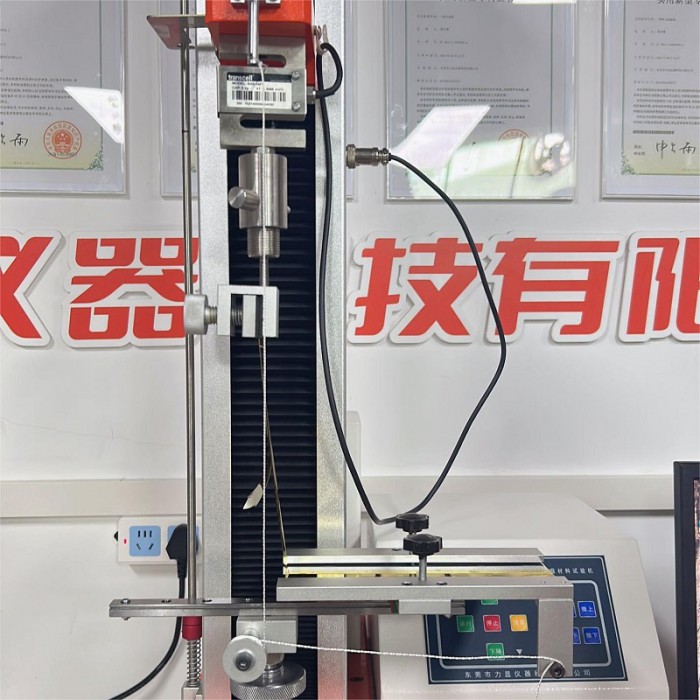

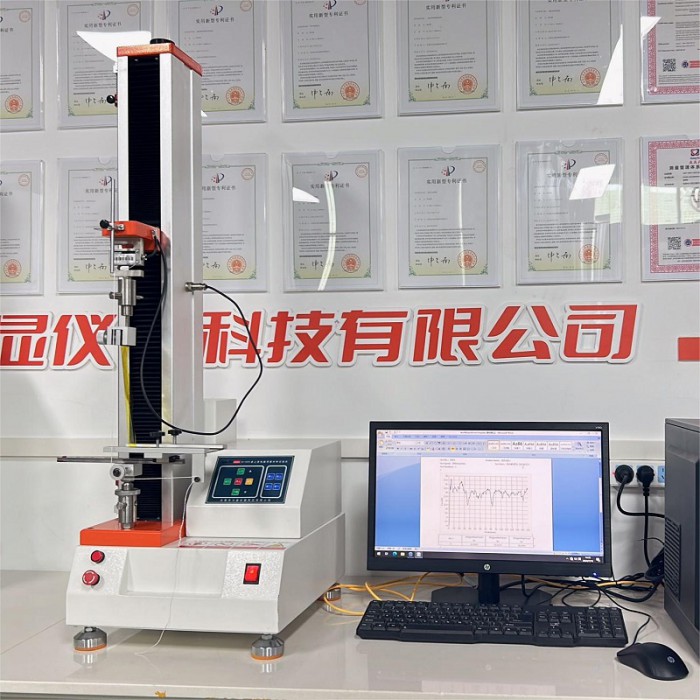

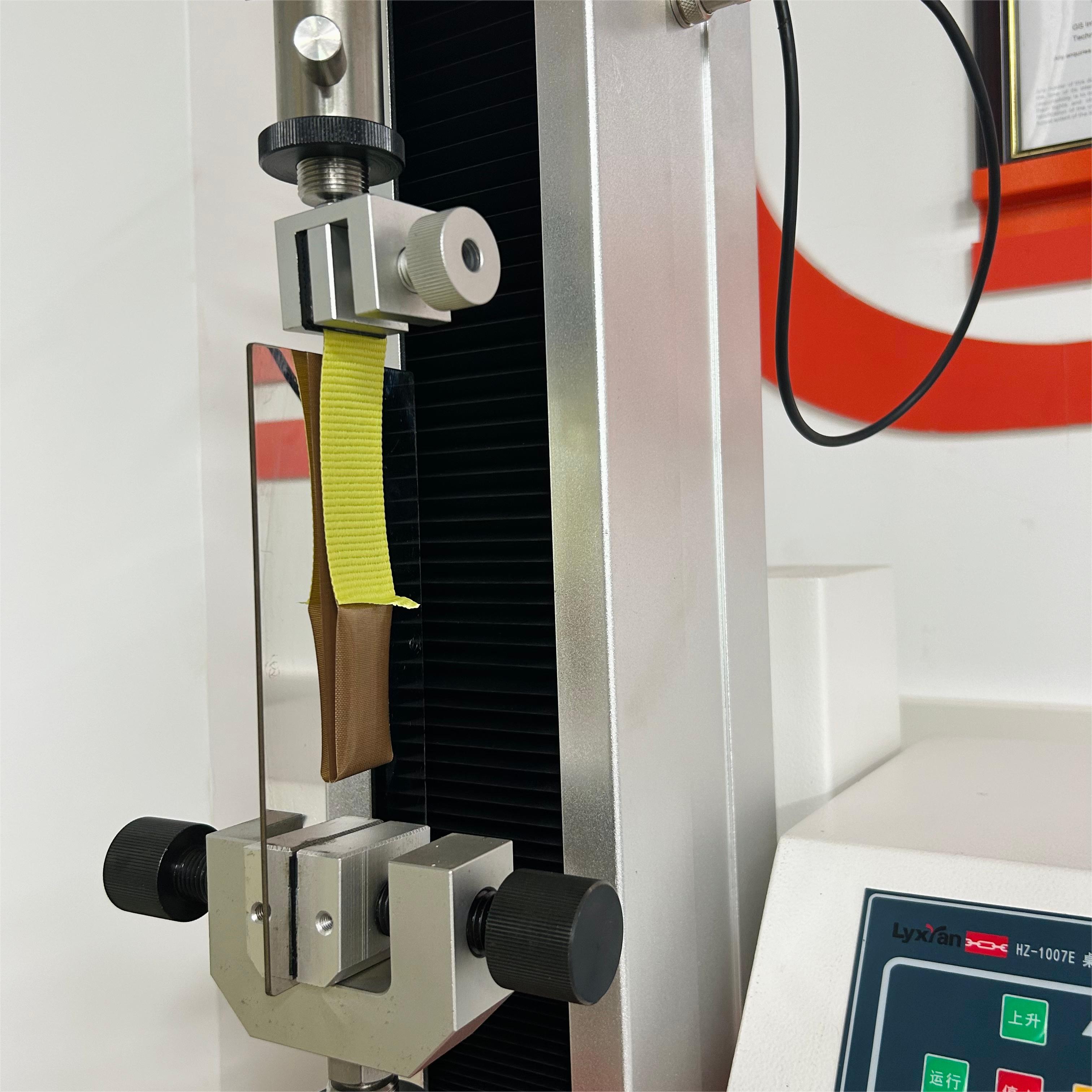

ASTM D3330 90° and 180° Plastic Film Adhesive Peel Test Equipment combine with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, Has high accuracy and sensitivity for the load, displacement measurement and control, Plastic Film Adhesive Peel Test Equipment using single-space structure, operational space at the bottom, it is mainly applied to test Peel Adhesion material which the load is less than 1KN, it has the parameters, such as stress, strain, control mode of displacement,calculated max force, tensile strength, bending strength, compressive strength, elastic modulus, rate of elongation, yield strength and others.

Main Features

1. Adopt deltaservo motor, the beam moves up and down to test the load through the transmission.

2.The whole control system is safe and high reliability.

3.Microcomputer control the whole testing process, real-time dynamic display the load values, displacement values, deformation, testing speed and testing curves.

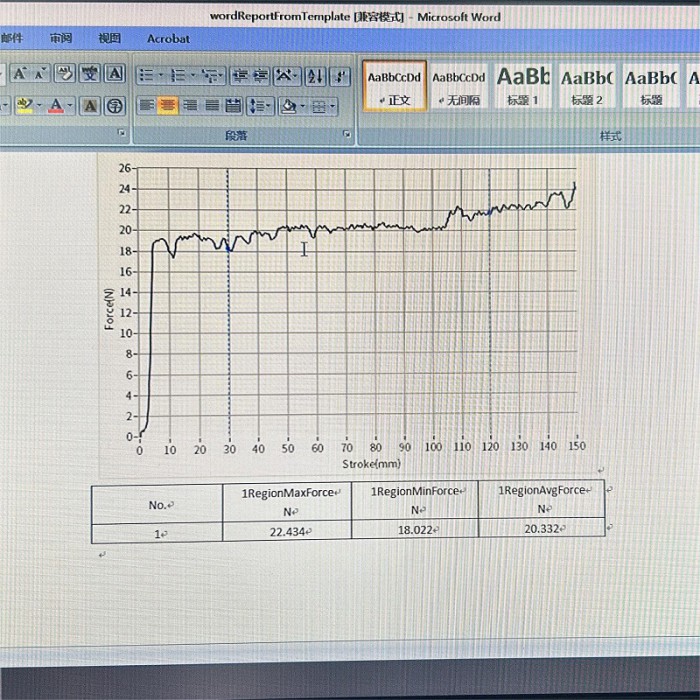

4. Microcomputer for data processing and analysis, testing results can be saved automatically, testing curve can be transferred out after the test, you can know the testing process through the testing curve, or compare with others curves, or amplify the curve.

5.The testing software of the Window, with strong processed capabilities of data and graphics, it can immediate print out a complete testing report and testing curves.

6.Has limit protection, overload protection, emergency stop and other safe protective functions.

1. Adopt deltaservo motor, the beam moves up and down to test the load through the transmission.

2.The whole control system is safe and high reliability.

3.Microcomputer control the whole testing process, real-time dynamic display the load values, displacement values, deformation, testing speed and testing curves.

4. Microcomputer for data processing and analysis, testing results can be saved automatically, testing curve can be transferred out after the test, you can know the testing process through the testing curve, or compare with others curves, or amplify the curve.

5.The testing software of the Window, with strong processed capabilities of data and graphics, it can immediate print out a complete testing report and testing curves.

6.Has limit protection, overload protection, emergency stop and other safe protective functions.

Specification